Weaving mills benefit from economic stimuli for the construction industry

Governments are currently trying to keep the economy going with pandemic economic stimulus programs to expand and rehabilitate national infrastructures. Both the construction sector and the textile industry are benefiting from the increased demand for construction textiles.

Geotextiles

So-called geotextiles are used for separating, stabilizing, reinforcing, filtering, draining, protecting and sealing. These are fleece or woven surfaces.

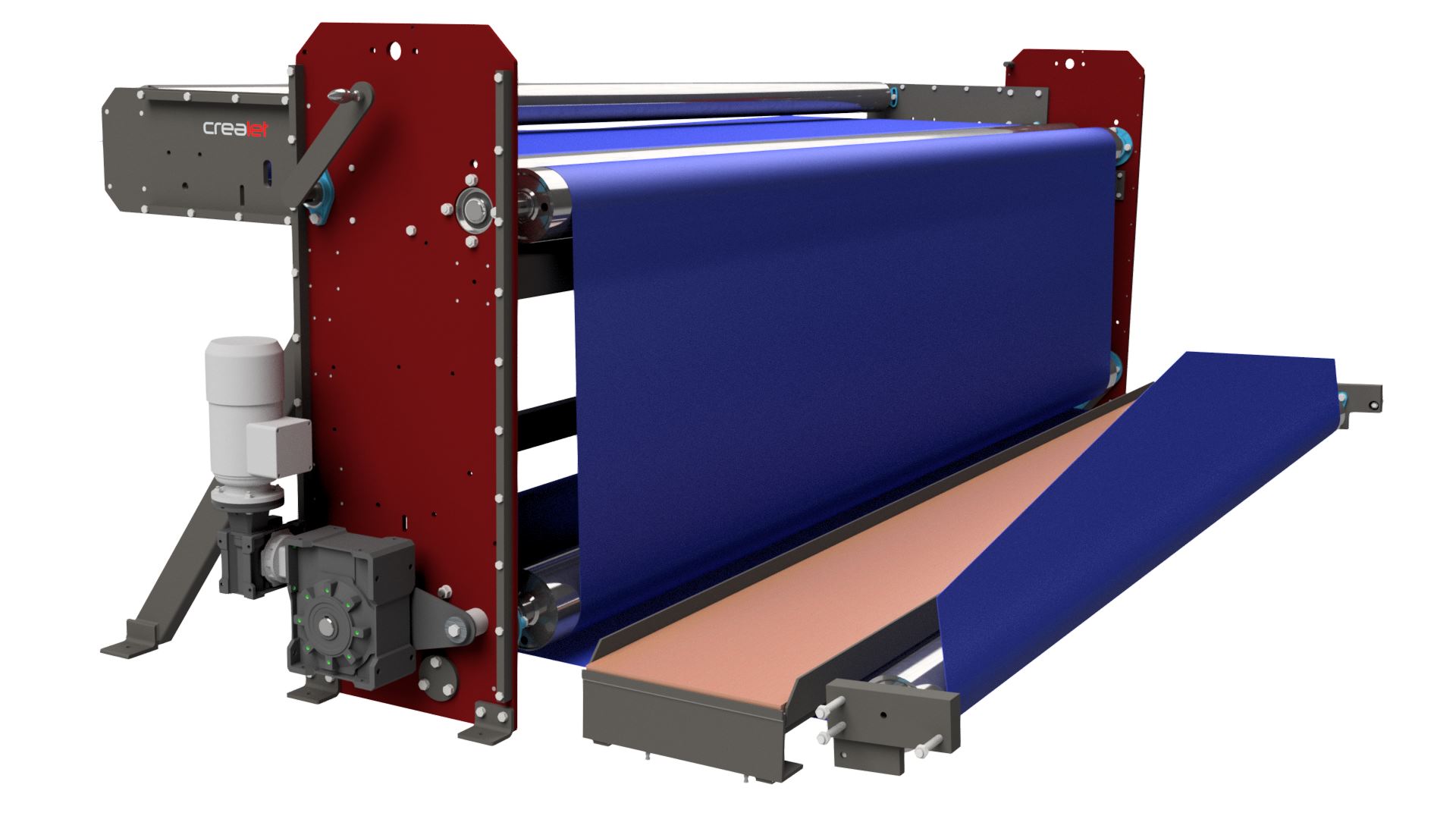

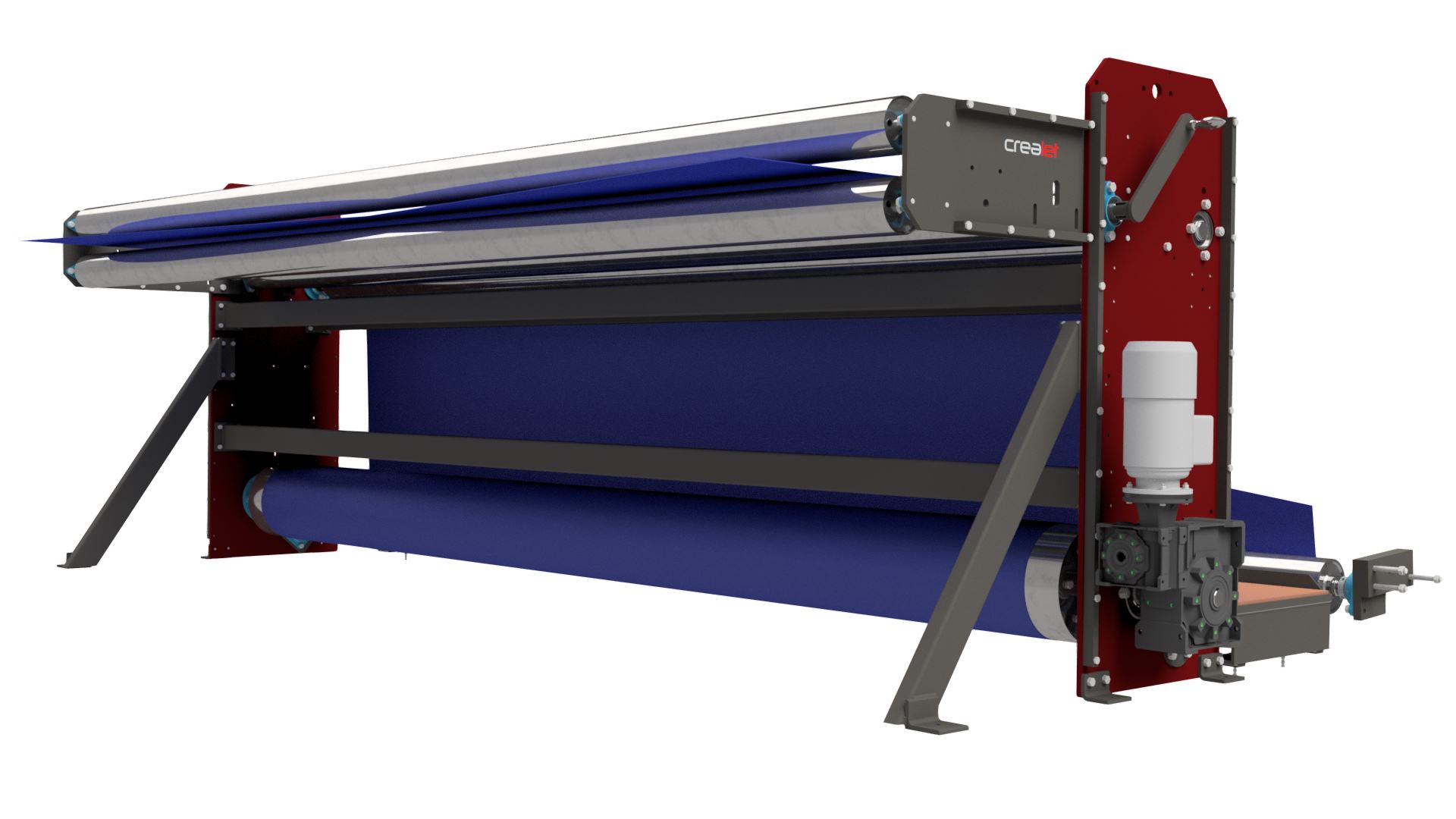

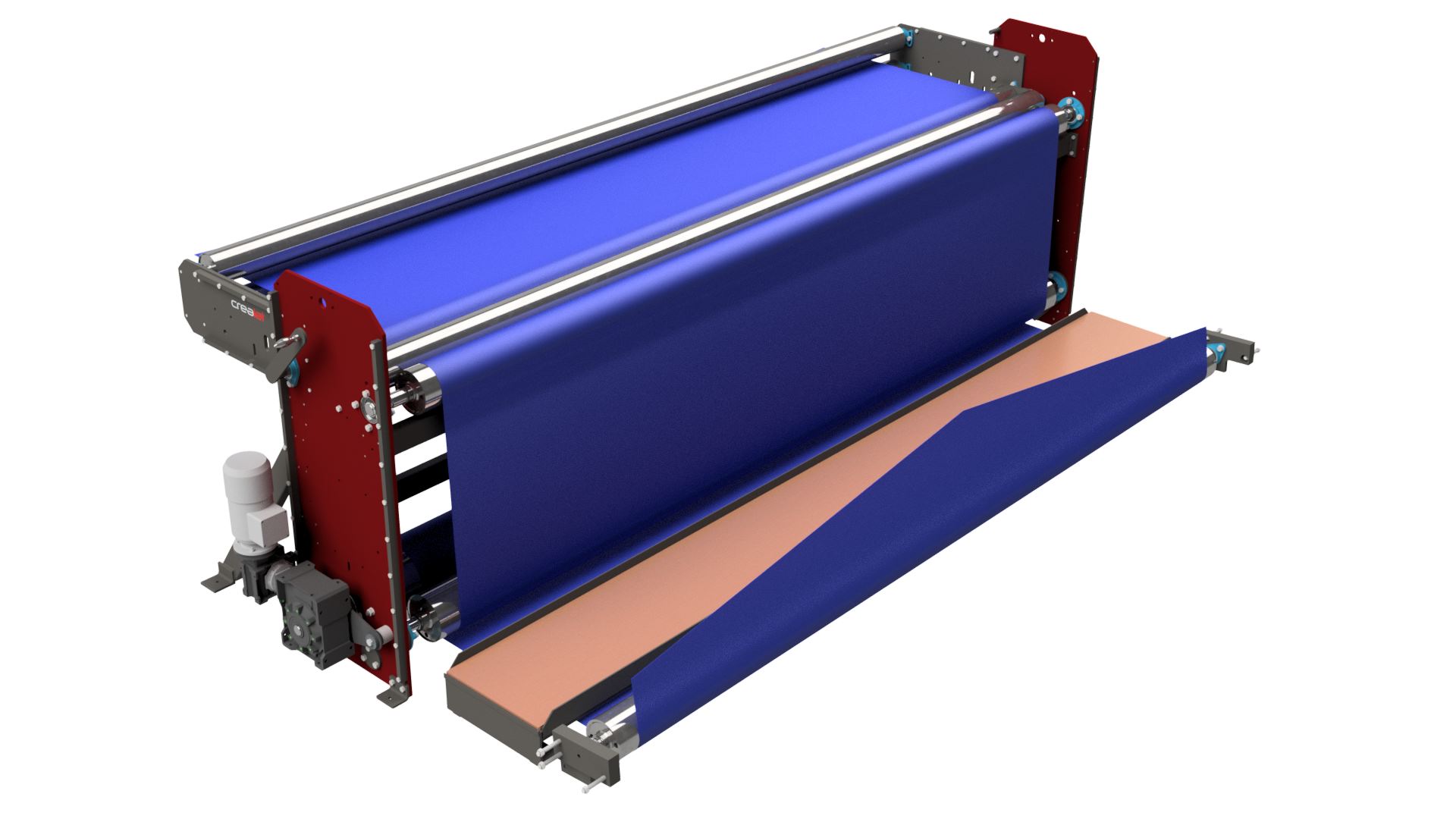

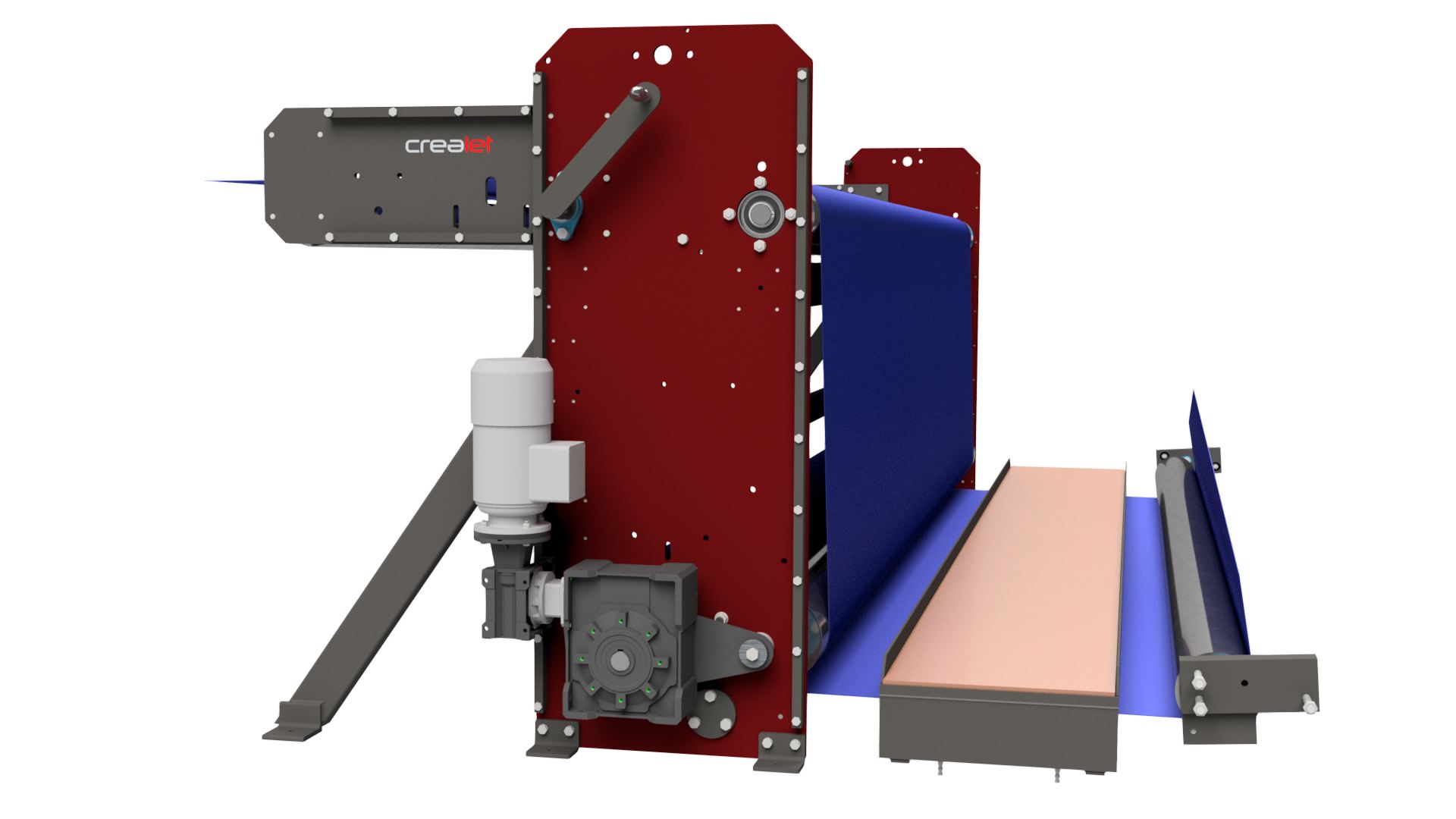

Geotextiles are often woven from creel. For a perfect feeding of the warp material CREALET offers the ideal warp yarn feeding device. Since 2003, the Swiss company has been developing solutions that are precisely tailored to the requirements of various applications.

Properly tensioned for geotextiles

The warp yarn feeding device controls the warp thread tension between the creel and the weaving machine. CREALET develops warp yarn feeding devices that feed the yarn to the weaving machine at a constant tension – electronically controlled. For geotextiles, a lower tension is usually required for the yarn take-off from creel than it is necessary for the actual weaving process.

Yet, for geotextiles applies too: highly developed creels pay off. The unwinding from creel must be perfect. Even with the best warp yarn feeding device it is not possible to compensate the tension fluctuations over the entire warp.

Experts for geotextiles and high-quality carbon fiber fabrics

Talk to our experts when it comes to feeding threads from creel to the weaving machine at the right tension – especially when it comes to geotextiles and high-quality carbon fiber fabrics. You can reach us at +41 55 286 30 20 or write to .

Have a look at CREALET’s products for wide waving.