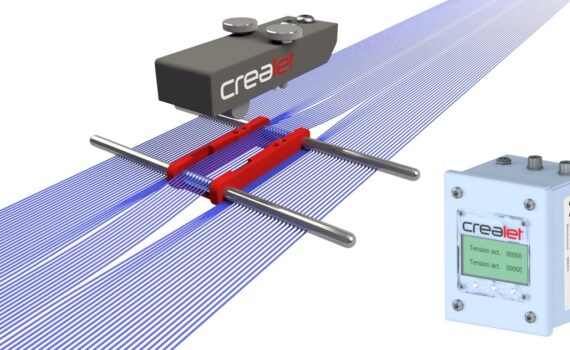

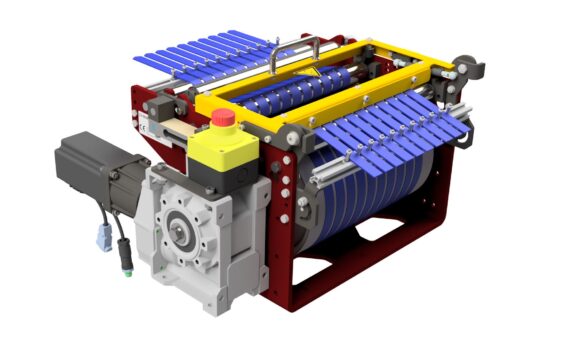

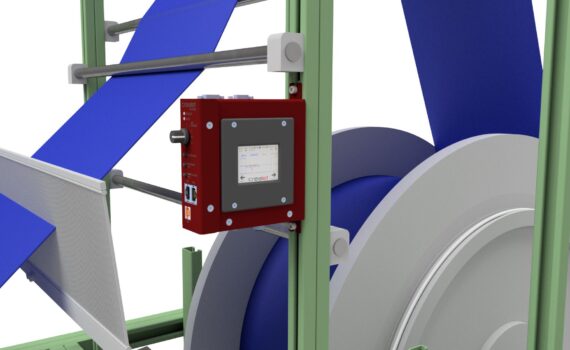

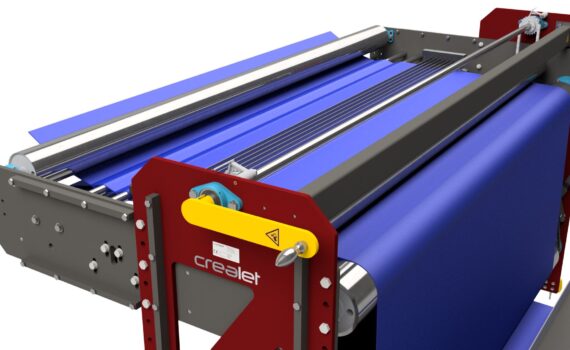

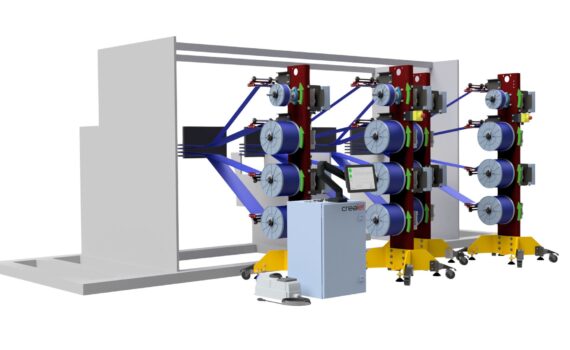

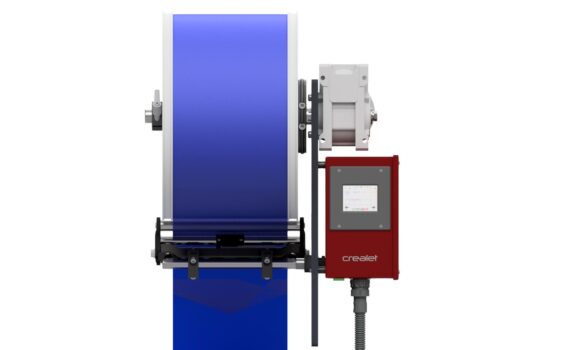

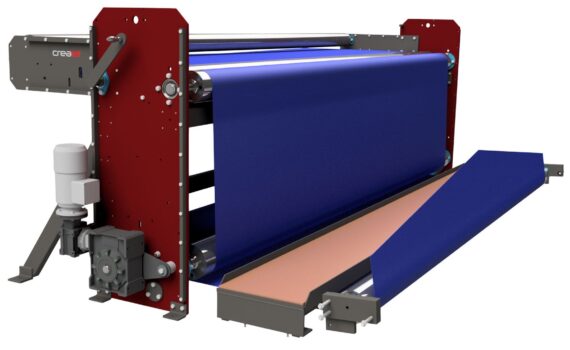

Crealet is the world leader in sophisticated warp feeding technology and tailored solutions. Controlled warp tension stands also for controlled fabric quality. The Swiss firm presents its latest developments for technical textile applications at Techtextil 2024 in Frankfurt, Germany.