Constant tension across the entire warp

Here is how you achieve constant tension.

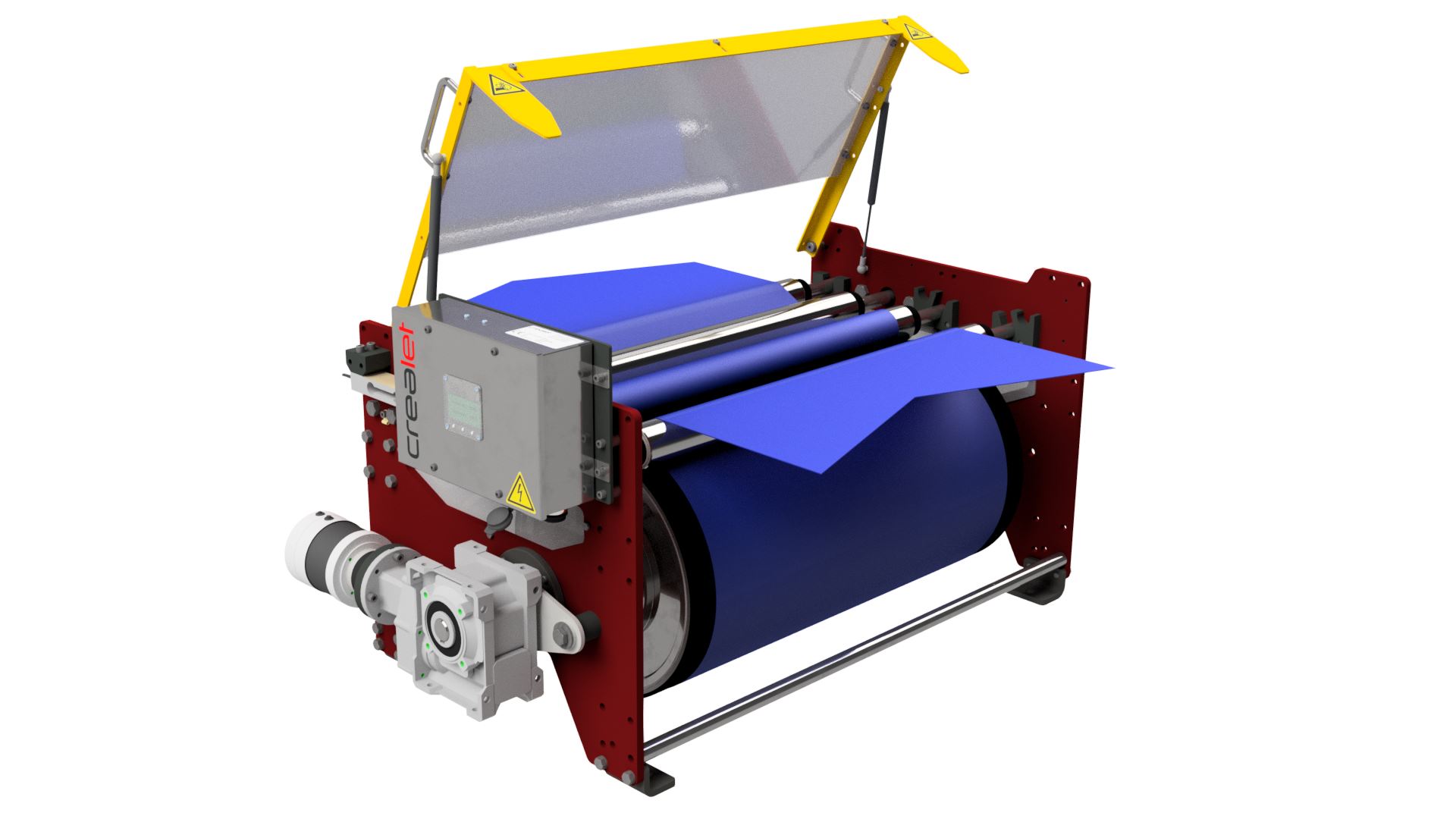

The warp feed unit controls the warp tension between the creel and the weaving machine. The feed roller delivers the warp material with the set tension to the weaving machine.

Usually the warp tension between the creel and the feed unit is less than the warp tension between the feed unit and the weaving machine.

The warp tension between the feed unit and the weaving machine is measured with a load cell and controlled by the control unit. The warp thread tension can be entered directly on the control unit.

At issue is good quality

There is no doubt that it is important to work with a good quality creel that keeps the tension fairly constant over the entire yarn group.

If the unwinding of the creel is not perfect, even the best warp feed unit cannot compensate for the tension fluctuations across the entire warp.