Controlled Thread Tension for Fabric Selvedges

Our long time experience in warp thread feeding for narrow and wide weaving machines and for warp knitting machines makes us your specialist in this discipline of textile manufacturing. Here are two examples in regard to selvedges: weaving brands into the selvedge and weaving of dense fabrics.

Example 1:

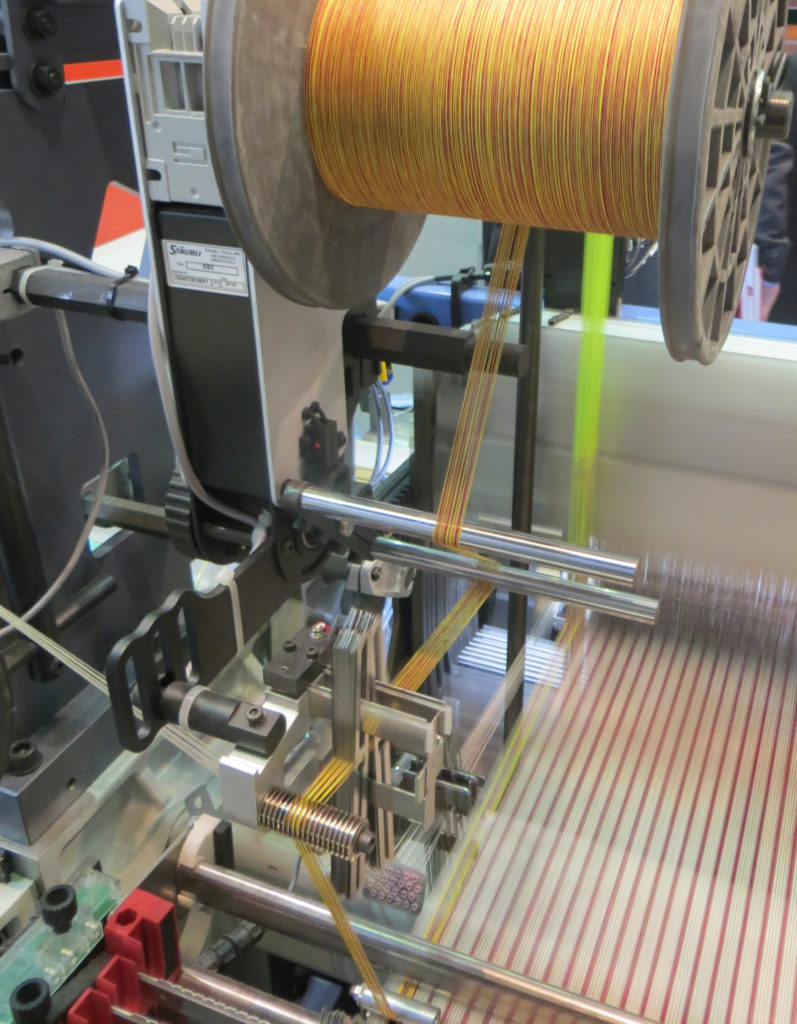

Weaving brands into the selvedge

The weaving of a brand into the selvedge serves to differentiate a product from the competitors and to underline its uniqueness. Thanks to woven-in brands customers benefit from better orientation in the market.

The inclusion of the brand into the fabric reflects a visual presence and is part of the overall corporate identity. Electronic Jacquard machines are especially suited for the inclusion of individual lettering in selvedges and in fabrics for a wide variety of applications.

Selvedge Thread Let-off CS2

In order to reach perfect quality, we recommend to deliver the selvedge threads from separate controlled bobbins.

The Key Advantages

- simple handling

- maintenance free

- independent adjustment of the selvedge threads

- reduce yarn breaks

- higher fabric quality

- for supplying fancy yarns or markers

- for all common disc coils

Technical Data

- Flange diam. max.: 300 mm

- Tube diam. min.: 40 mm

- Full width of bobbin max.: 210 mm

- Max. warp tension: 96 N

- Voltage supply: 24VDC

Example 2:

Wavy selvedges in dense fabrics

When weaving dense fabrics, it can happen that the selvedges of the fabric are looser than the rest of the fabric. Due to the wavy fabric selvedges, such fabrics can be further processed only with difficulty, because the selvedges cannot be kept at the same tension as the rest of the fabric.

Often dense fabrics are coated in a second stage. Also during this coating wavy selvedges have a negative effect. Because of the loose selvedges a uniform coating of the fabrics is hardly possible.

These disadvantages can at least be minimized by feeding the selvedge yarn from warp bobbins to the weaving machine, which allows the yarn tension to be set accordingly.

Our selvedge let-off guarantees a constant warp tension from full to empty warp bobbin. The devices can be equipped with a tension indicator to ensure the reproducibility of the tension settings.

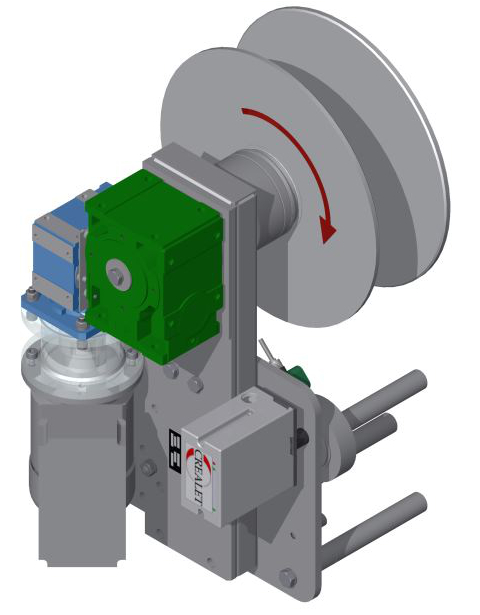

Selvedge Thread Let-off SOLEX

Selvedge Thread Let-off SOLEX

To eliminate the negative effects, the selvedge thread can be fed to the weaving machine over separate let-off systems, which allows to fine-tune the needed thread tension.

The Key Advantages

- simple handling

- maintenance-free

- independent adjustment of the selvedge threads

- reduction of wavy selvedges

- higher fabric quality

- for supplying fancy yarns or markers

- for all common disc coils

Technical Data

- Flange diam. max. 400 mm

- Tube diam. min.: 70 mm

- Full width of bobbin max.: 210 mm

- Warp tension max.: 40 kg

- Voltage supply: 230V AC

Customer specific and future oriented solutions

We develop and construct individual components for the feeding of all sorts of materials, such as wires, glass and optical fibers, stranded wires, carbon fiber, high performance fibers and flat strips.

There are different requirements for let-off systems, depending on the manufacturing process, the physical characteristics of the feeding material, the required tensions and speeds.

We apply our expertise to discuss with you the best possible solution for your tasks.

The modular build of our components allows for flexible combinations and adjustments. The ideal way for customer specific solutions for a wide variety of applications.

We are looking forward to hear about your special product requirements and your suggestions.