Warp Tension Control and Resource Optimization

Non-uniformity or inconsistency of warp tension is responsible for wastage in the classical doctrine of lean production.

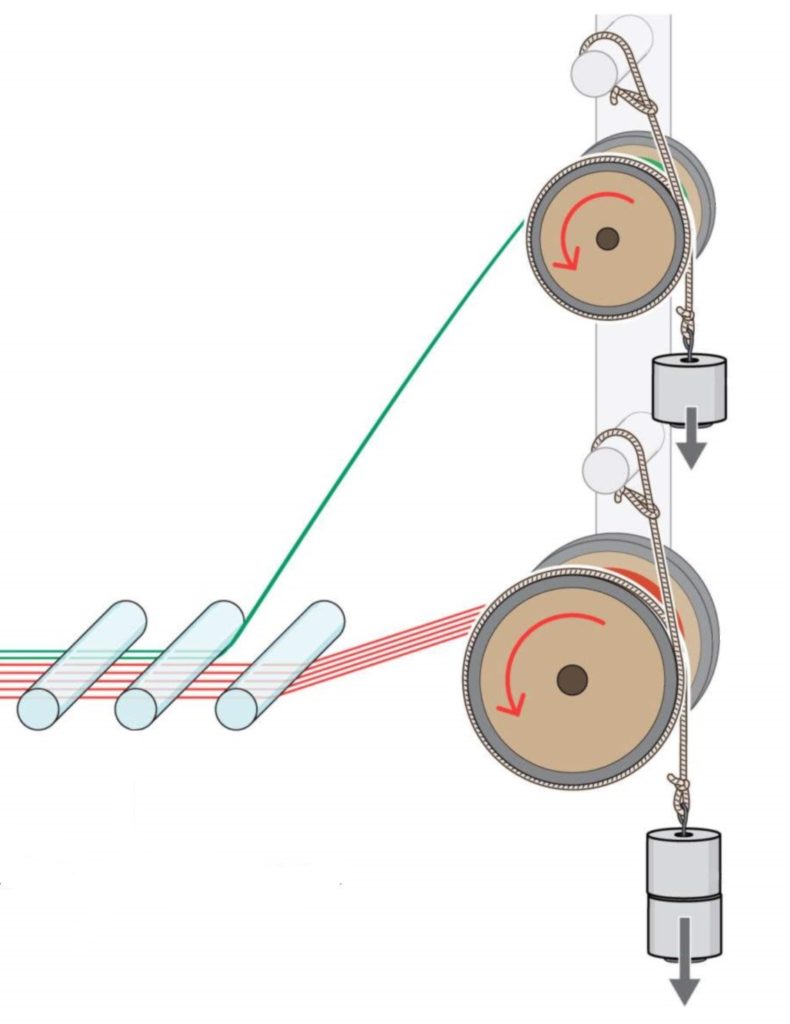

In tape weaving mills, tape or rope brakes with weights are often used to generate warp tension.

As the warp beam diameter decreases, however, these weights must be continuously reduced in order to keep the warp yarn tensions within a somewhat acceptable range.

This wastes employee resources that could be used for value-added processes.

We are currently working on solutions using suitable actuators, sensors to electronically control the existing tape and rope brakes to eliminate the need to change weights.

This will eliminate waste of human labor, increase fabric quality and achieve higher profitability.

This solution is suitable for controlling warp tension on a small budget, while generating human resources to carry out value-added activities with it.

We would be pleased to explain our ideas and development progress to you in a personal meeting.