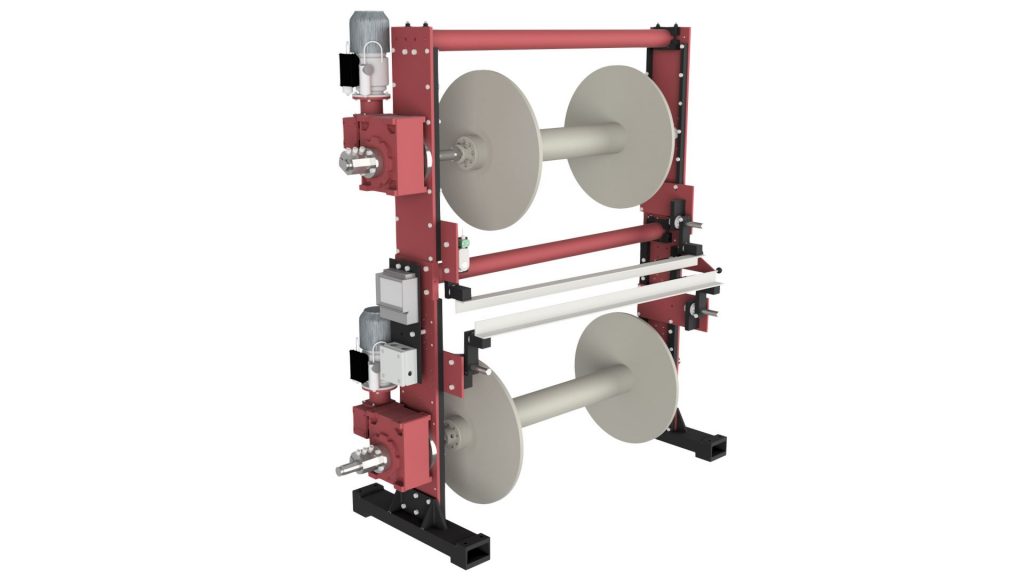

Tailored warp beam frames for ribbon weaving

In the past, an electronic warp feed for ribbon weaving was rather difficult to implement, mainly due to the associated costs. Today, new manufacturing processes and methods enable cheaper solutions.

An electronic feed of the warp threads not only has a positive influence on product quality, it also reduces machine load and warp breaks.

With the electronic feed of the warp threads, warp beams with a larger flange diameter can be used, whereby the efficiency of the weaving machine can be increased.

Powerful drives and motions

With modern and powerful drives and motions, CREALET delivers intelligent and process-oriented drive variants for the control of warp threads.

Industry 4.0 and the Internet of Things (IoT)

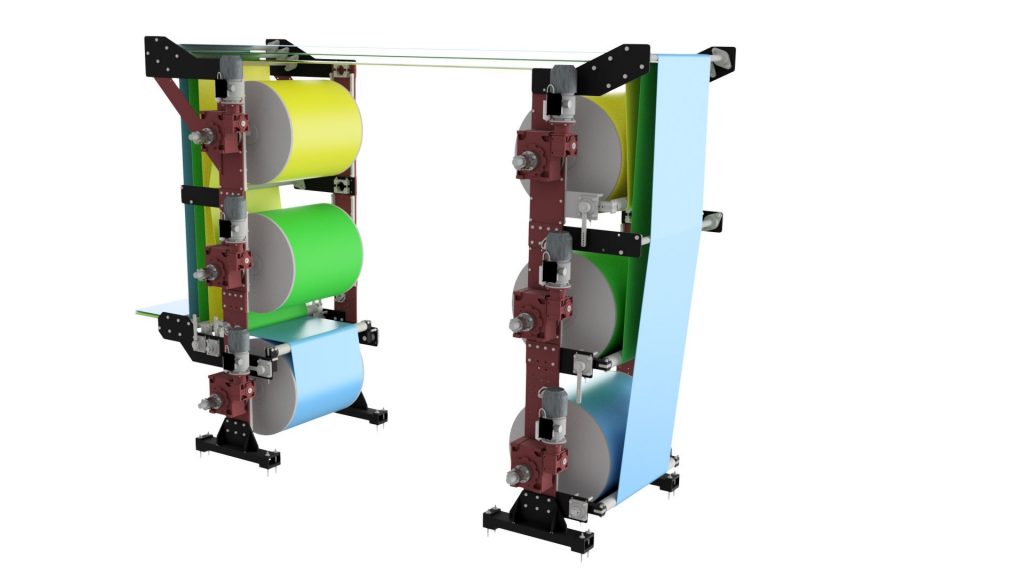

Industry 4.0 and the Internet of Things (IoT) are challenges that we face now and in the future. We can realize solutions that precisely and quickly synchronize the thread tension of different warp beams and link them together in an intelligent system combination.

Integrated safety and comfort features

In addition, our motions offer integrated safety and comfort features which not only include functional safety in the overall system network, but also the capabilities of communication and diagnostics, and enable measured value acquisition and signal processing in the context of a comprehensive overall process.

Warp feeding systems according to your needs

CREALET designs and manufactures warp feeding systems according to your needs. Years of experience and expertise in this area as well as the cooperation with innovative partners speak for us.

Therefore, do not hesitate to explain your problem in the field of warp feed, whether you are weaving from the creels, the sectional warp beams or the wide warp beams. Our team is working to find the best possible solution for you.