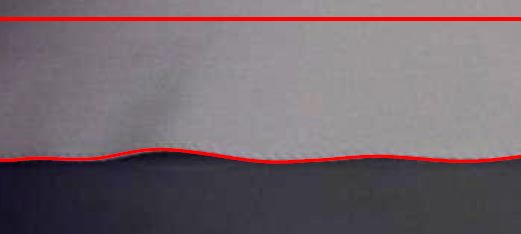

Wavy selvedge zones due to uneven tension

Several studies show that during weaving, the warp tension is not absolutely constant across the fabric width. Warp tension is lower in the selvedge zones and increases towards the middle of the fabric.

The reason for these warp tension differences over the fabric width is the slip of the weft yarn inwards at the fabric selvedge zones. The effect of this are wavy selvedge zones which cause a number of problems in terms of fabric quality and manufacturing efficiency.

On the one hand these wavy selvedge zones cause difficulties in further processing the fabric. And on the other hand they are the reason for an increase in machine stops due to more warp yarn breaks near the selvedge.

In order to avoid this phenomenon we have developed a selvedge thread let-off. The selvedge threads are on separate bobbins on both sides of the weaving machine and allow the warp tension to be set individually.

With our SOLEX add-on the wavy selvedge can be avoided or at least significantly reduced.

SELVEDGE THREAD LET-OFF SOLEX

Guarantees a constant warp tension

When weaving dense fabrics, it can happen that the selvedges of the fabric are looser than the rest of the fabric.

When weaving dense fabrics, it can happen that the selvedges of the fabric are looser than the rest of the fabric.

Due to the wavy fabric selvedges, such fabrics can be further processed only with difficulty, because the selvedges cannot be kept at the same tension as the rest of the fabric.

This is referred to as wavy selvedges. This waviness has a negative effect especially during unwinding or rewinding of the fabric.

The wider the fabrics are produced, the more distinctive the waviness becomes.

CONSTANT WARP TENSION GUARANTEED

Often dense fabrics are coated in a second stage. Also during this coating wavy selvedges have a negative effect. Because of the loose selvedges a uniform coating of the fabrics is hardly possible. These disadvantages can at least be minimized by feeding the selvedge yarn from warp bobbins to the weaving machine, which allows the yarn tension to be set accordingly.

Our selvedge let-off guarantees a constant warp tension from full to empty warp bobbin. The devices can be equipped with a tension indicator to ensure the reproducibility of the tension settings. A further improvement can possibly be achieved when weaving from several warp bobbins by using different warp tensions.

![]() — simple handling

— simple handling

![]() — maintenance-free

— maintenance-free

![]() — independent adjustment of the selvedge threads

— independent adjustment of the selvedge threads

![]() — high warp tension possible

— high warp tension possible

![]() — higher fabric quality

— higher fabric quality

![]() — max. bobbin diam. 400mm

— max. bobbin diam. 400mm

![]() — max. warp tension as required

— max. warp tension as required

![]() — max. feeding speed as required

— max. feeding speed as required

TENSION INDICATOR

It is a small device for the measurment and display of process tension. The digital unit is zeroed and calibrated.

WARP BOBBINS

For natural and man-made fibers.

SEMI-AUTOMATIC WARPING MACHINE

For natural and man-made selvedge thread yarns, as well as for tapes on warp bobbins. The warping machine is equipped with the latest control and operating technology.

Related Products:

The Selvedge Thread Let-Off SOLEX is perfect for tensions >10N.

For tensions <10N we recommend the Selvedge Thread Let-Off CS2.