Designed with the latest technology.

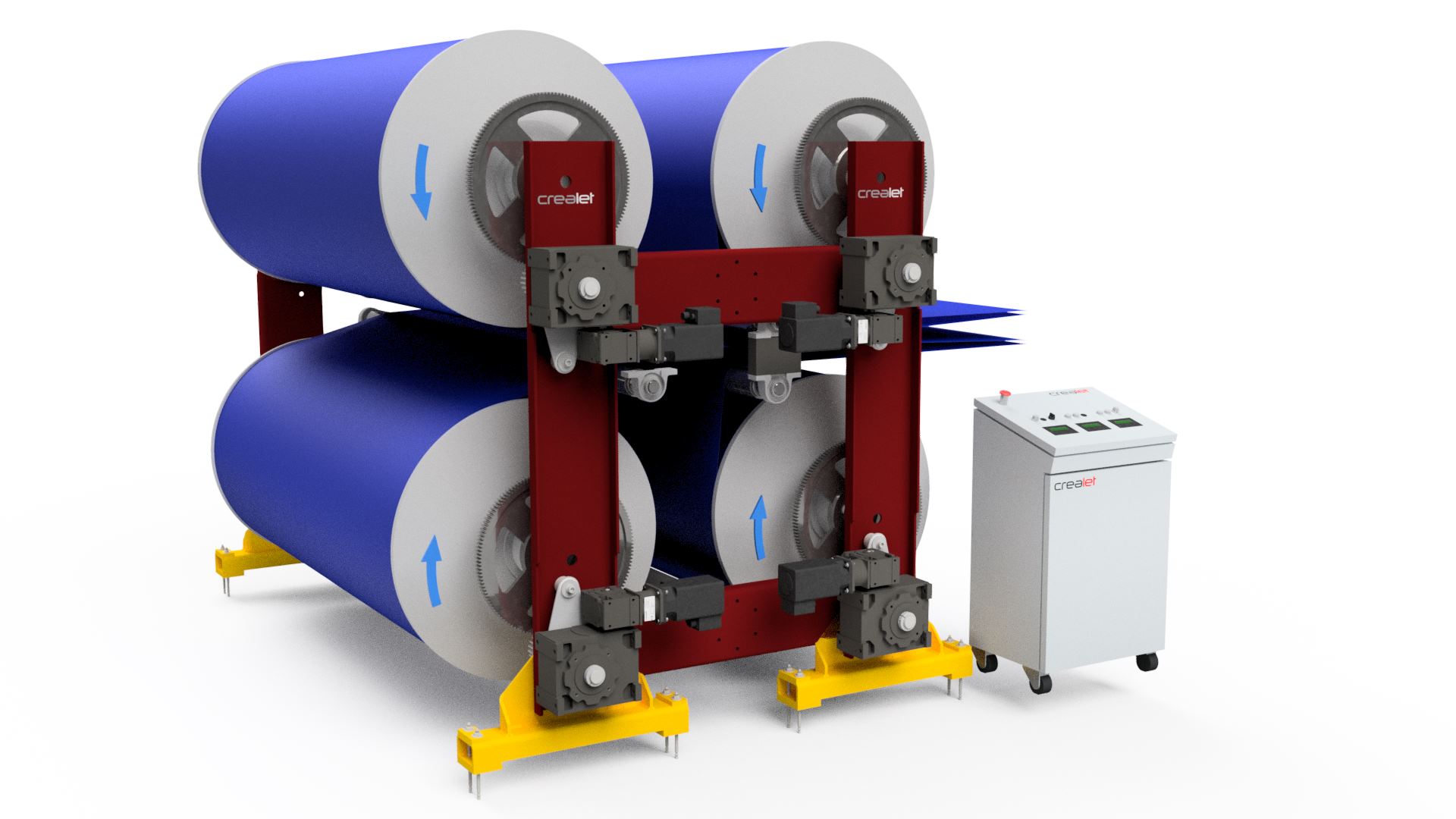

Warp beam stands are used for various kinds of applications, ranging from the weaving fabrics with coarse yarn counts, use of warp yarns with widely differing yarn counts or for multi-layer fabrics with a different weave-in of the binder yarn.

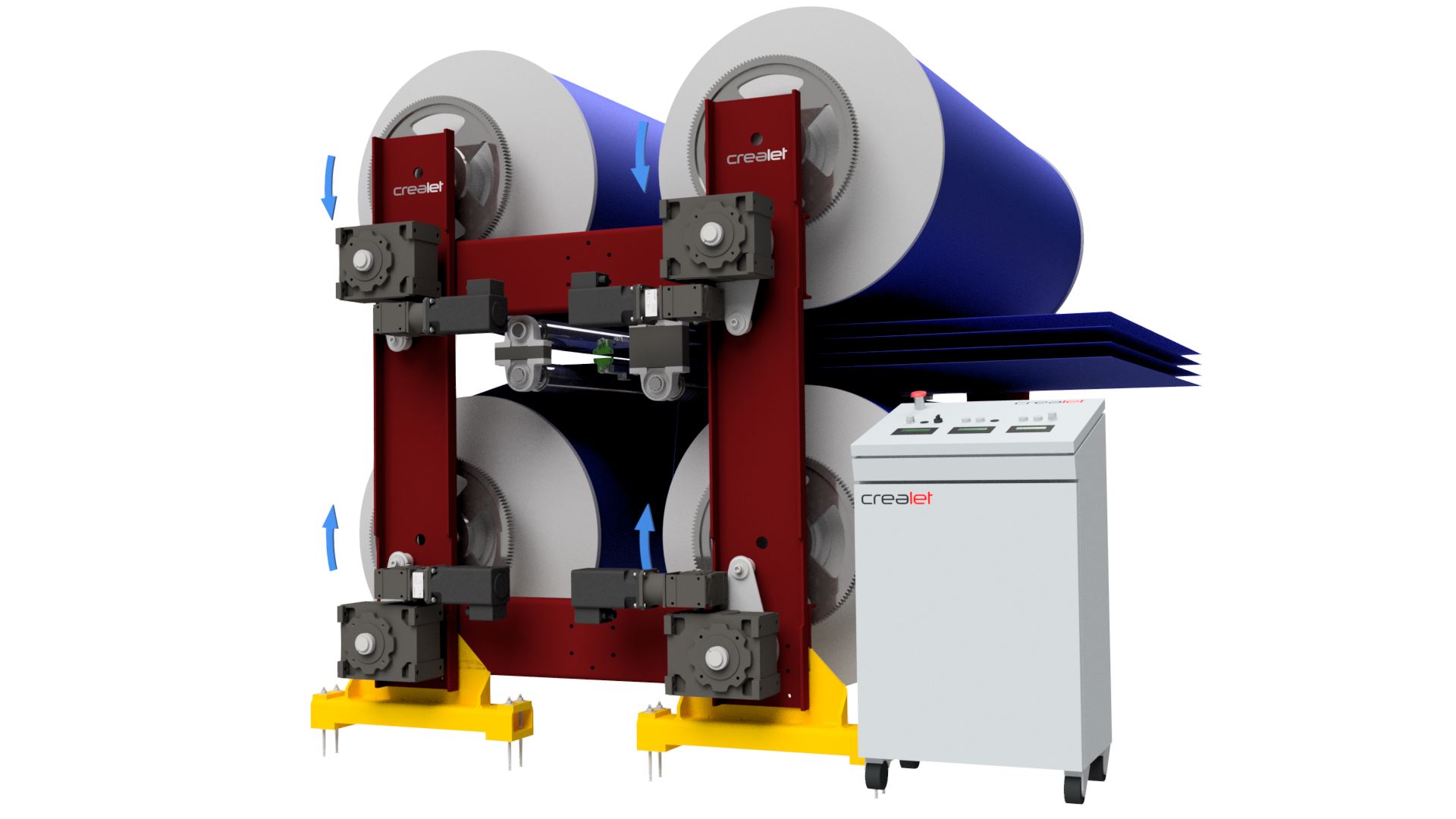

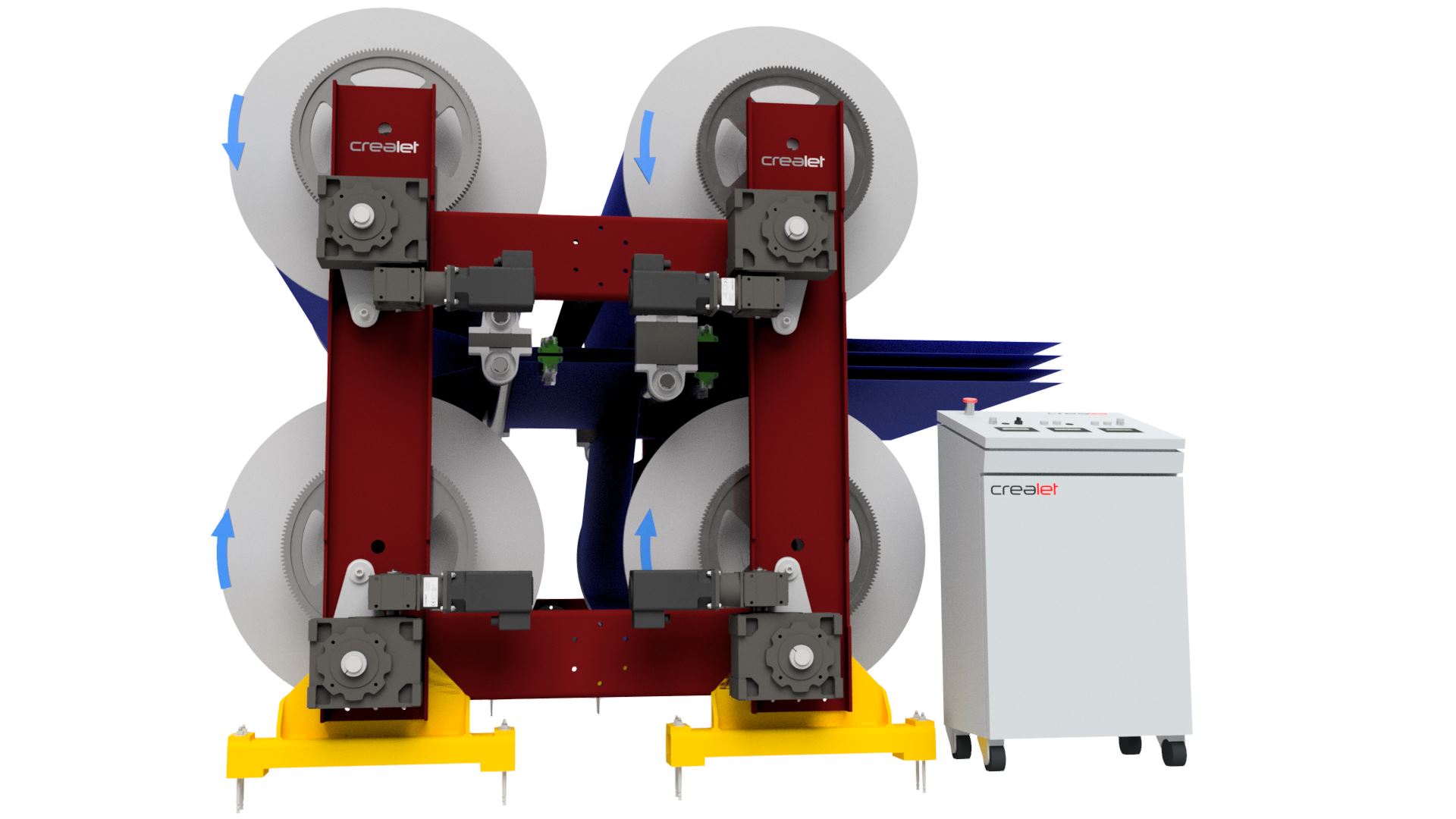

The warp beam stands are designed with the latest technology and especially for the easy handling of the warp beams during loading and unloading; and incorporate electronic controls for feeding the required amount of yarn with the requested tension to the weaving machine.

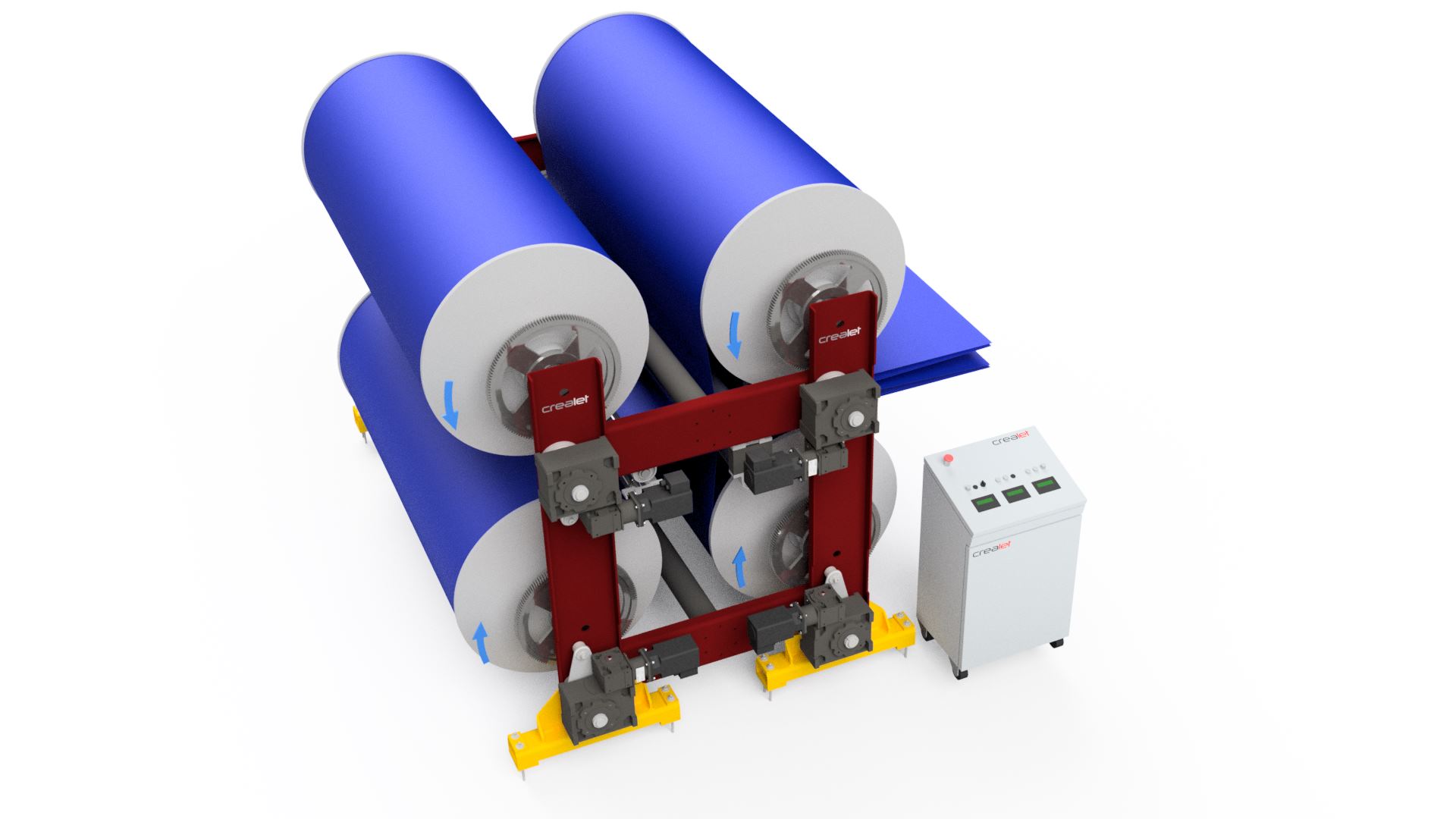

In the case of fabrics that are woven in large quantities over a lengthy period and where traditional size warp beams are quickly woven out, warp beam stands can make the weaving process more efficient and economical.

The larger the diameter of the beams the longer the length of the warp that can be wound on to it and the fewer the warp changes required, but the greater the tension variations that have to be compensated.

The most modern machines can take warps of up to 1100mm in diameter. If even larger diameter beams are needed for very coarse yarns, the beams can be placed onto separate warp beam stands outside the weaving machine. They can be placed either above or behind each other.