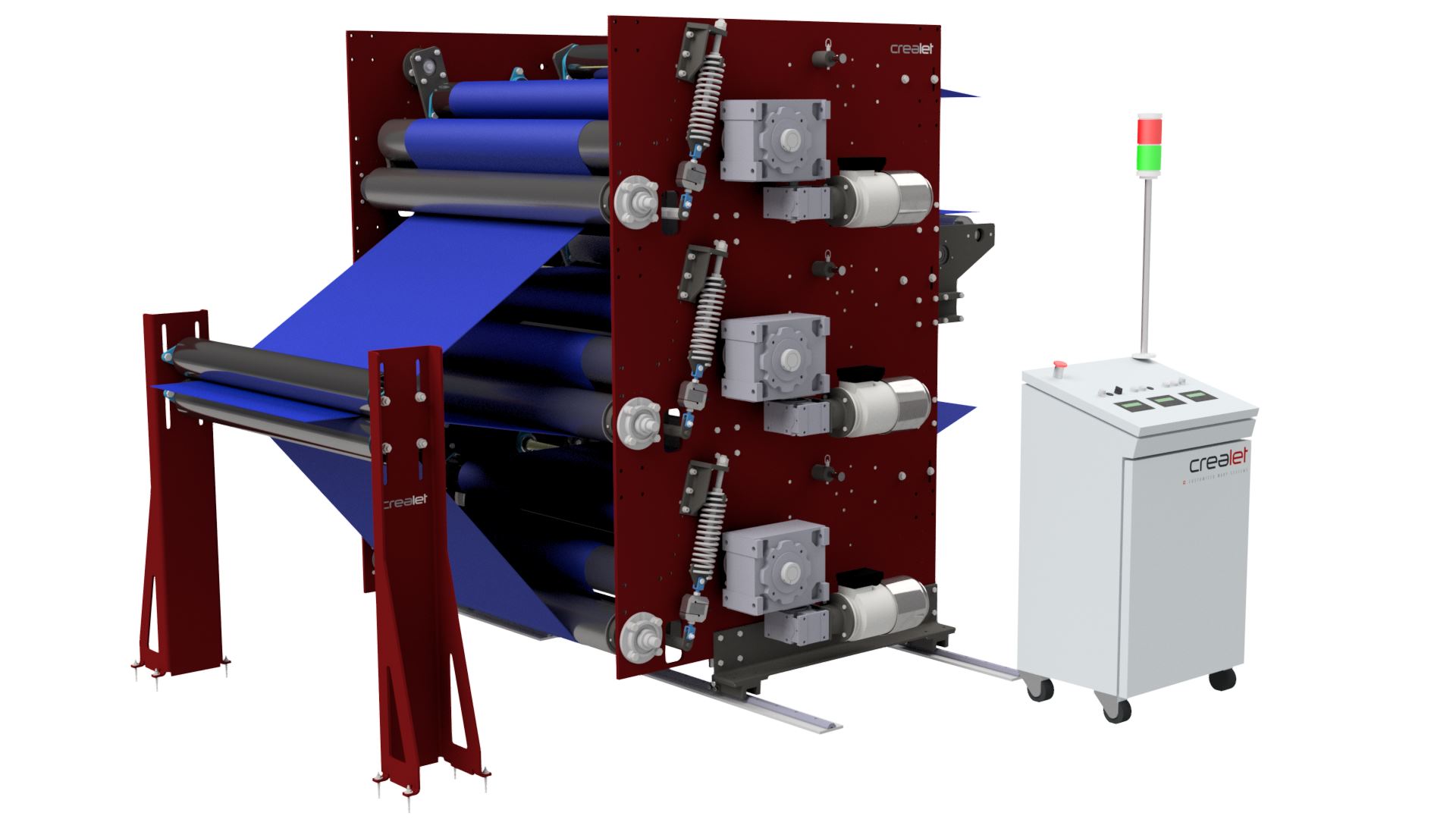

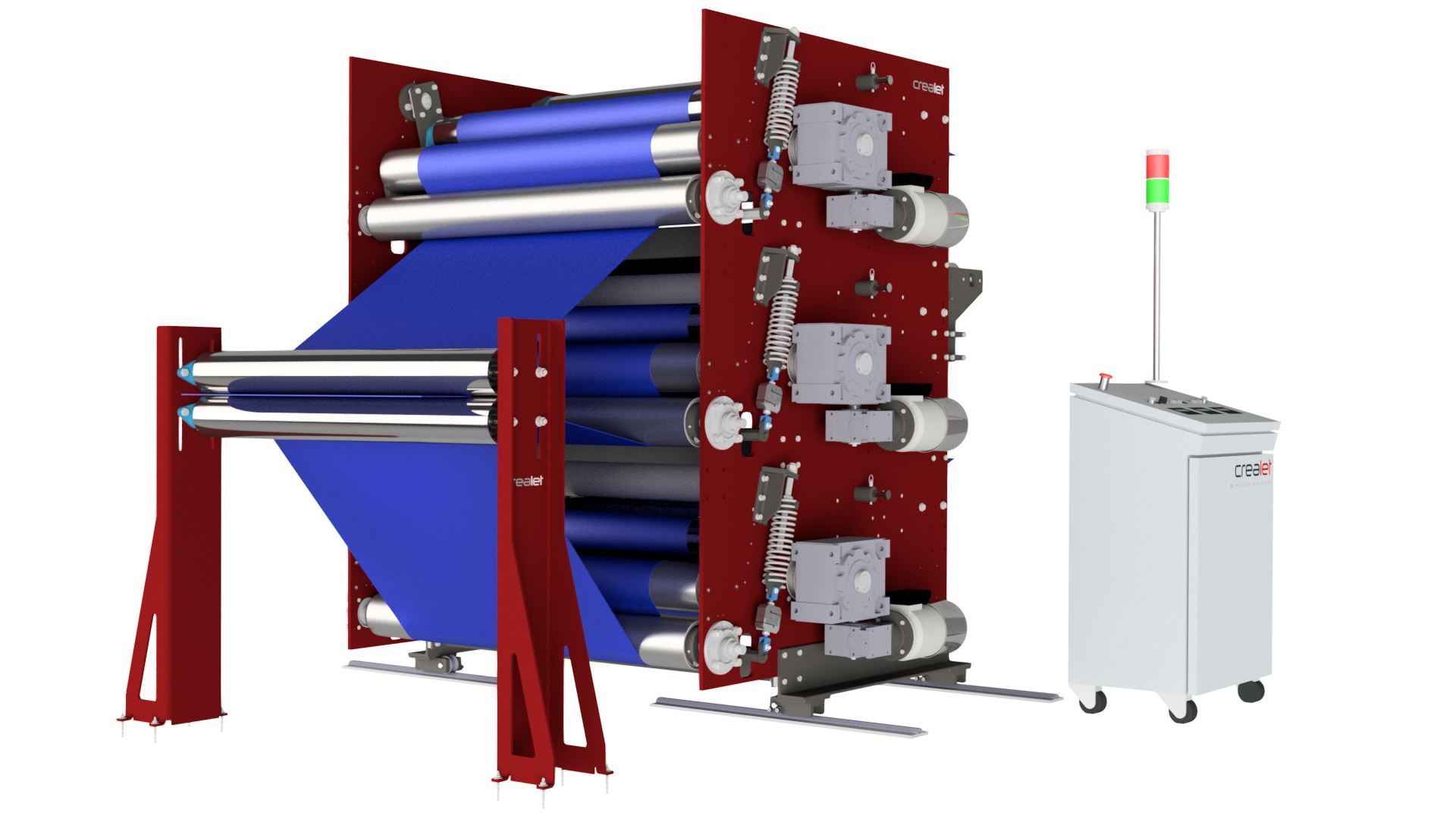

Multiple warp in-feed systems for narrow and wide weaving mills.

A multiple warp in-feed system consists of several in-feed rollers that draw off the warp yarn from the creel or from several warp beams.

Such solutions are used when there is a risk of the warp yarns overlapping on the in-feed roller or when the warp tensile forces are high.

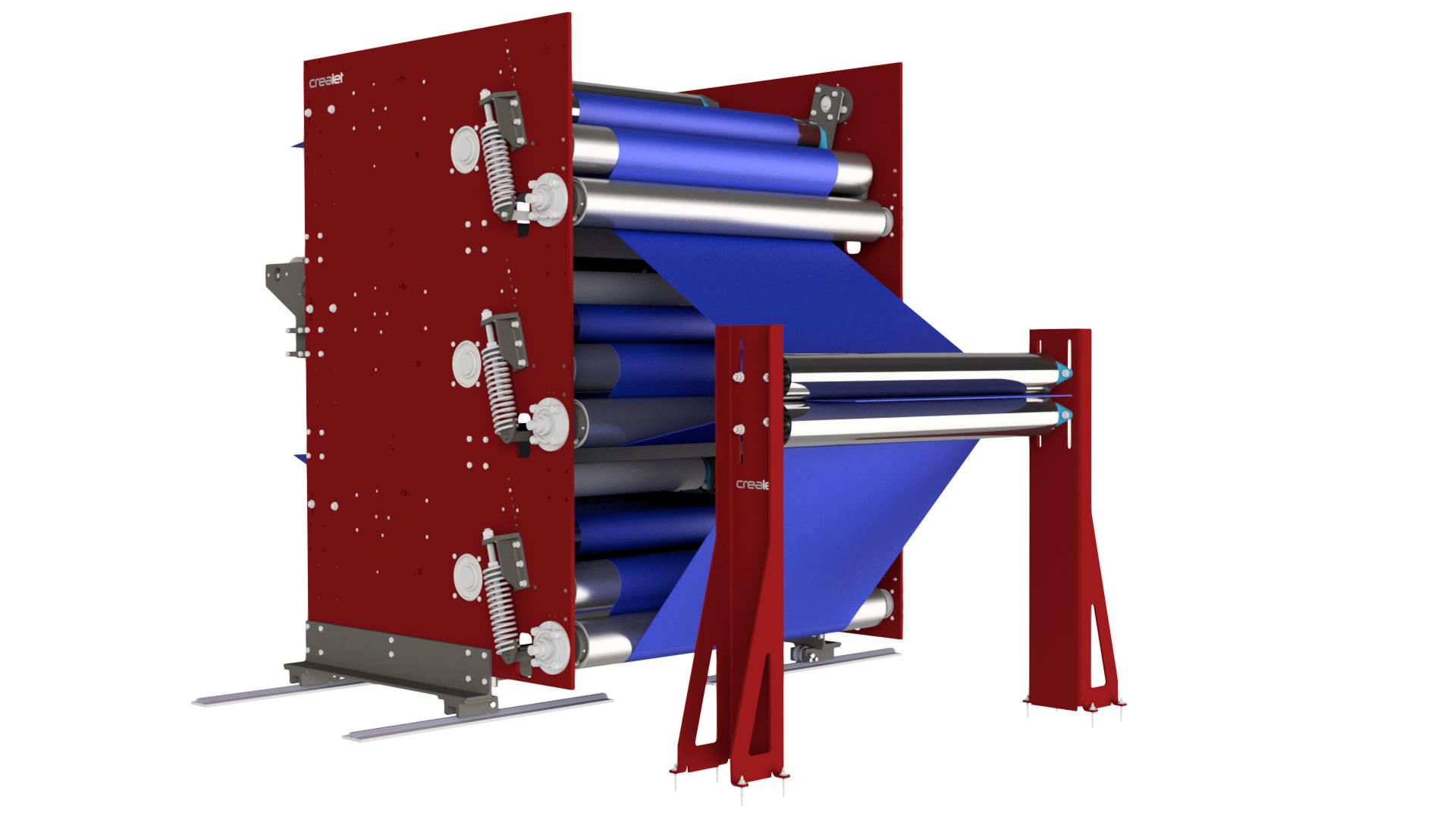

Weaving multi-layer fabrics

Even when weaving multi-layer fabrics, multiple in-feed systems can be used depending on the fabric structure. The reason for this may be that different warp yarns are used or different weave-in of the warp yarns is necessary.

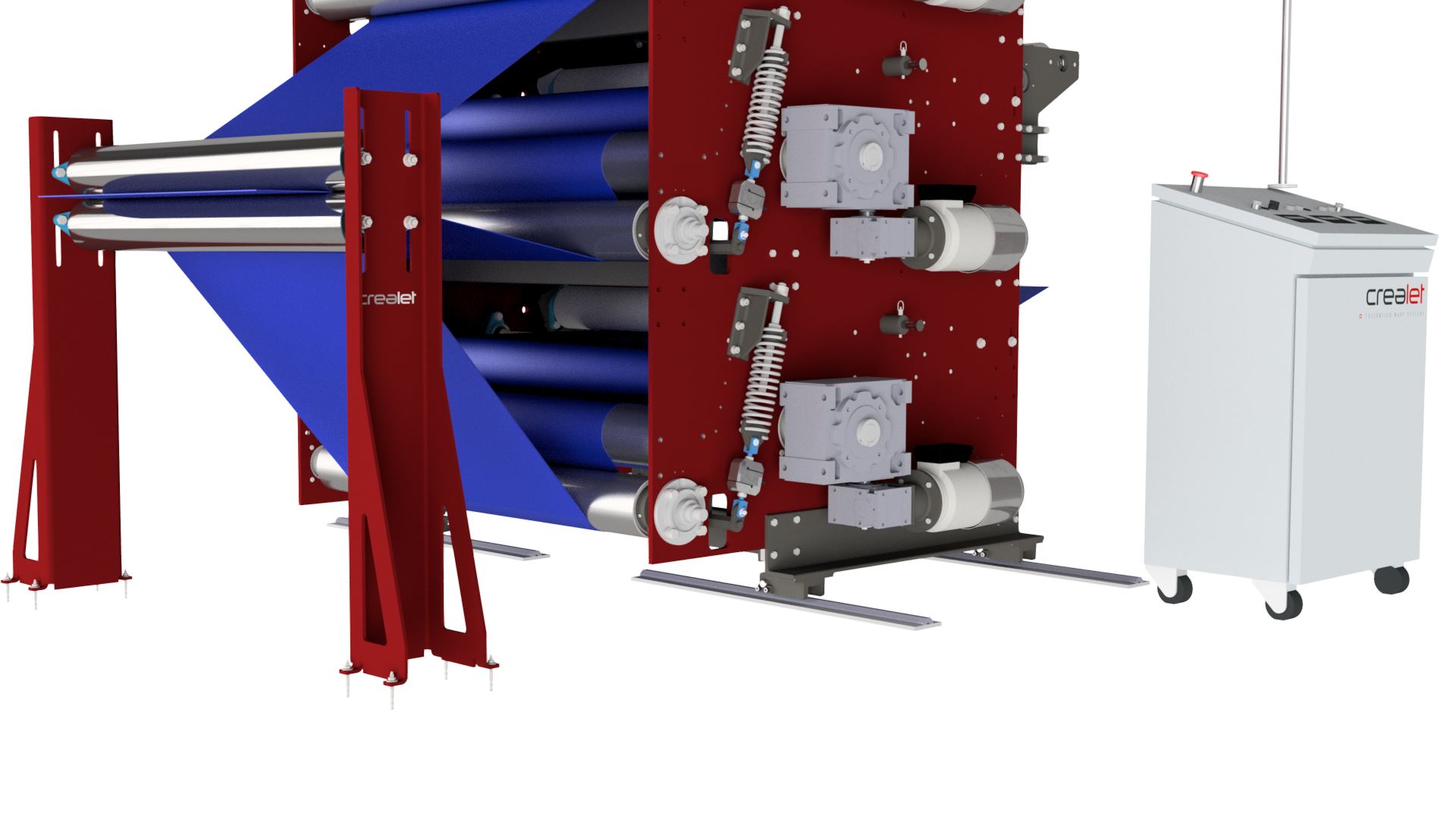

For such applications, we have built multiple in-feed systems for ribbon and wide weaving with up to 6 feed-in rollers. Such delivery mechanisms can be arranged above the weaving machine or freestanding behind the weaving machine.

Abandonment of the warp in-feed system

The task of the in-feed System is to pull off the warp material from the yarn storage media such as warp beams or creel and feed it to the weaving machine in the correct quantity and tension. It is important to consider several factors such as delivery roller dimensions, surface properties and accessibility.

Add value from experience

New requirements are constantly changing the production process. The need for unique solutions is the constant with which we are happy to support you.