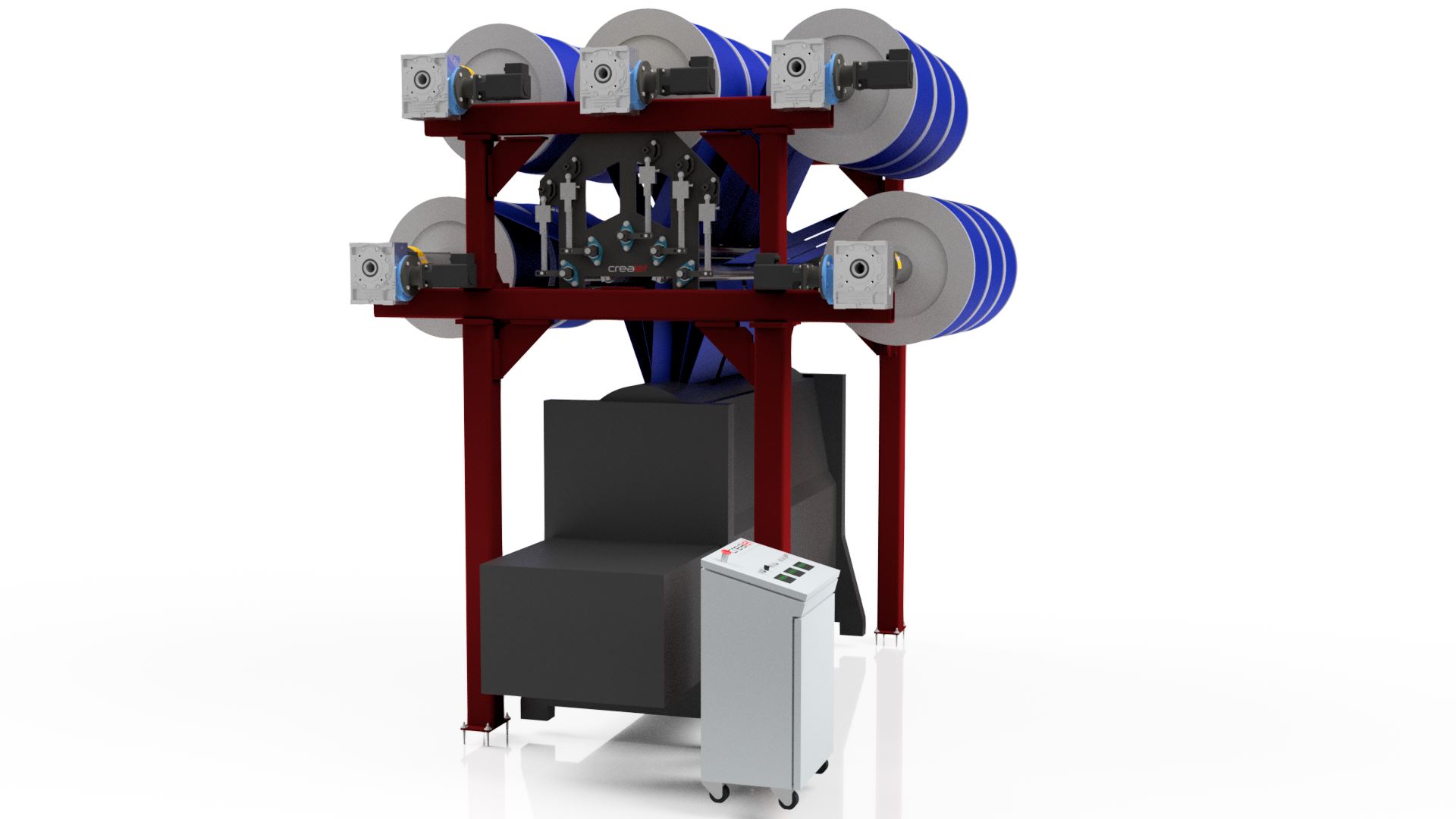

Warp knitting machines require a large amount of yarn which is fed to the machines from creels or warp beams.

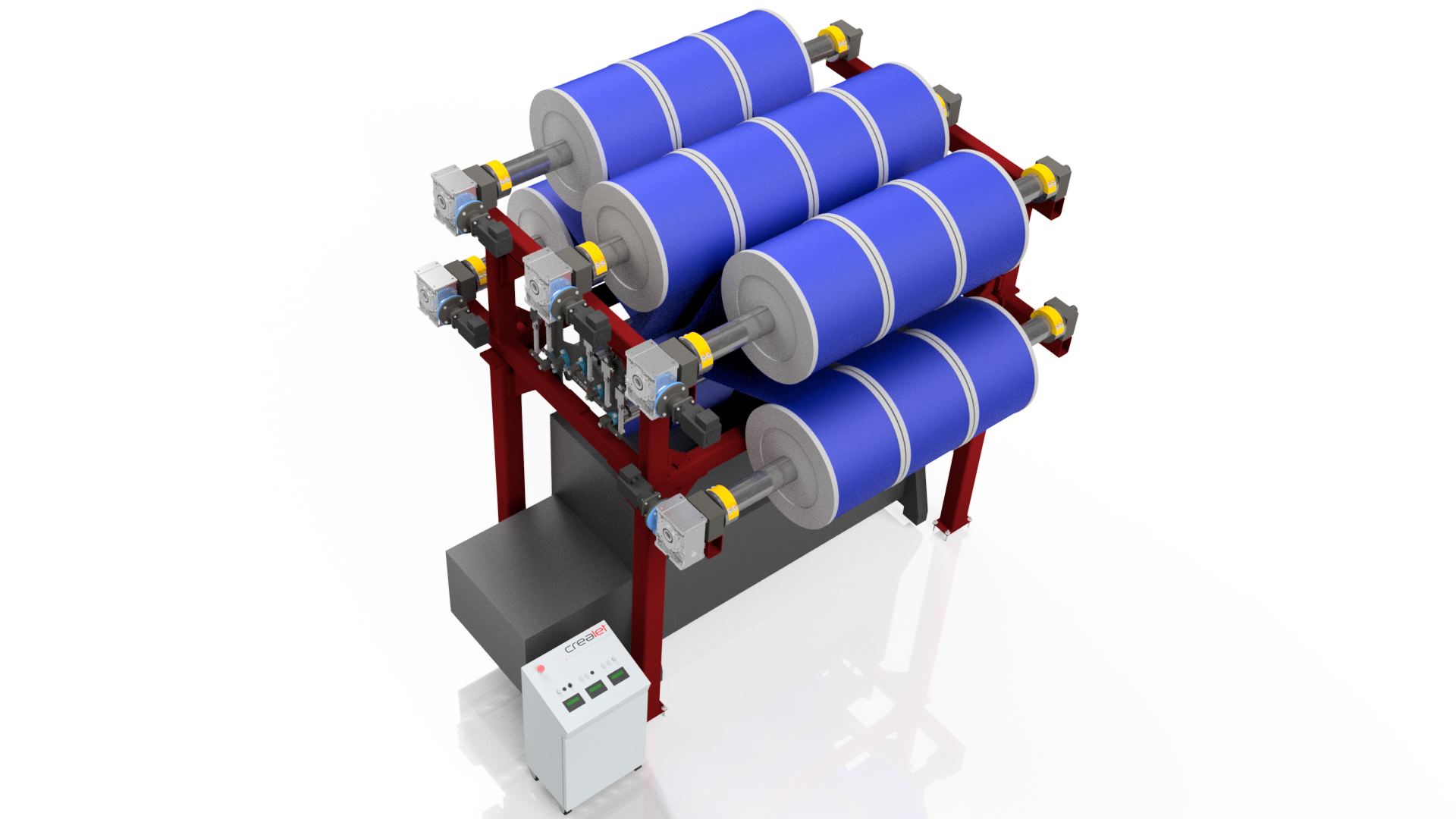

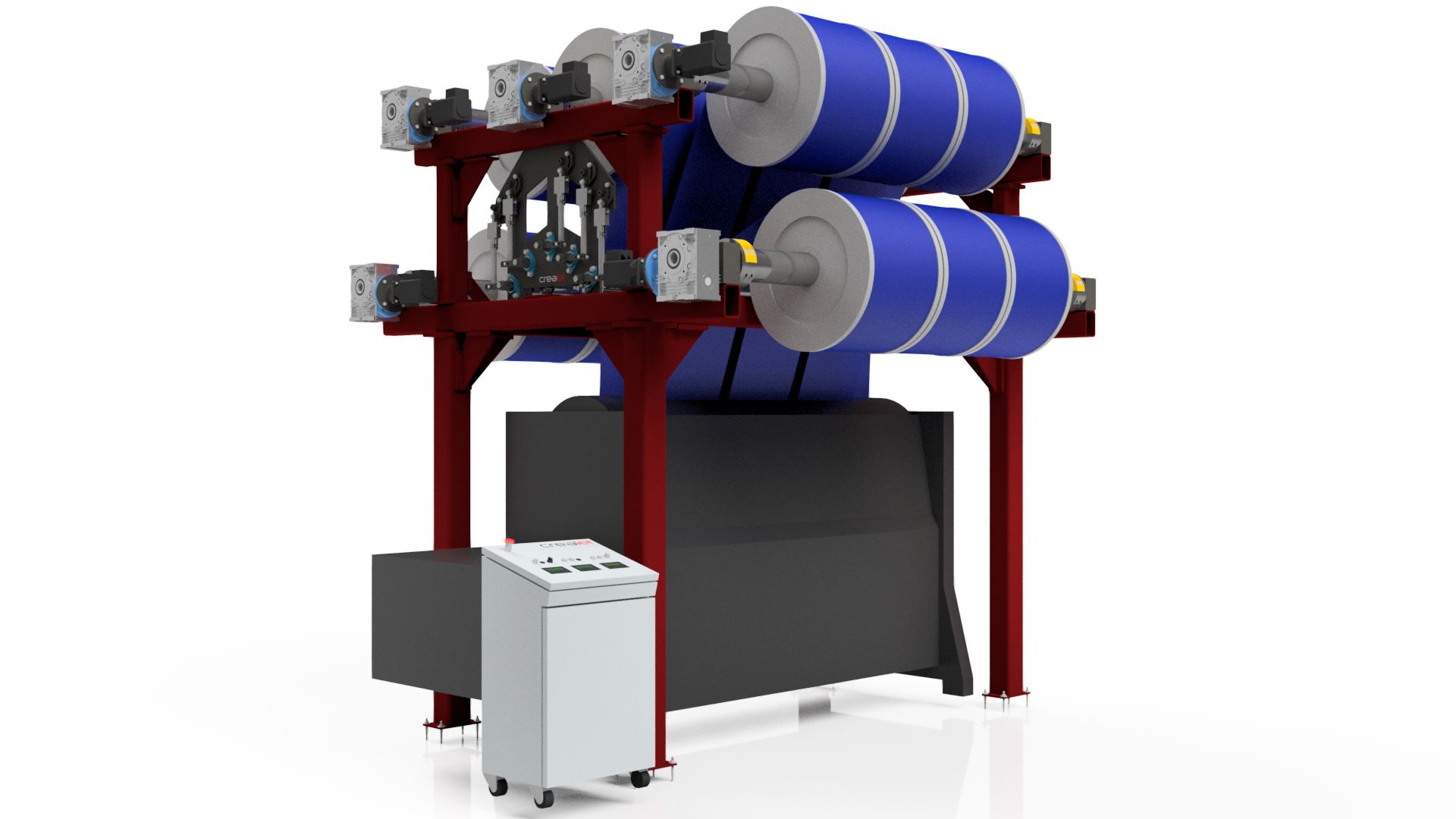

The knitting machine fed units draws the required amount of yarn from the warp beam or creel. In warp beam applications, these can be arranged above or next to the knitting machine.

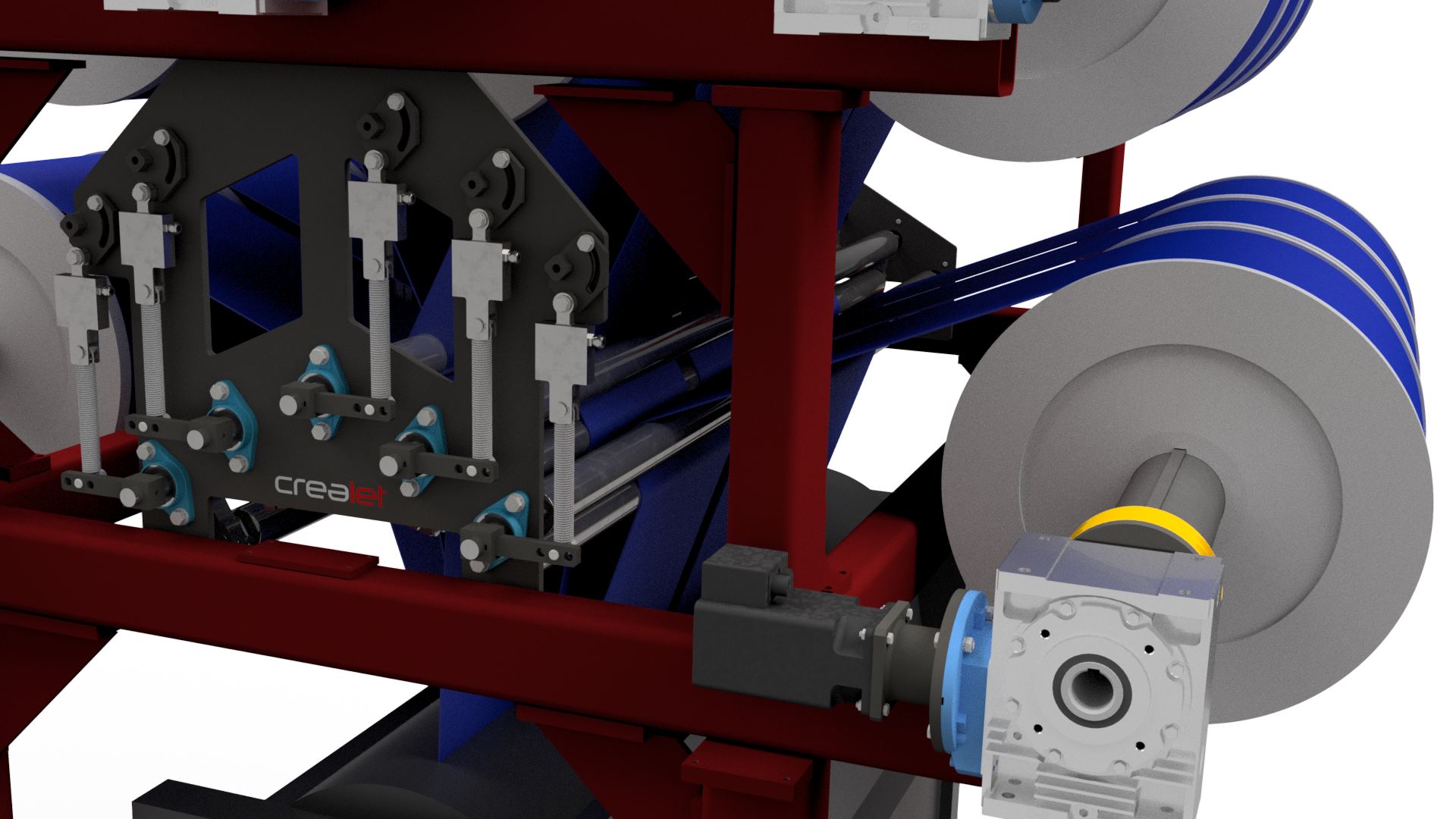

We implement customer-specific projects in the area of tension-controlled thread feeding. Modifications or complete solutions consisting of warp beam storage, tension sensing and control can make the knitting process more efficient and economical.

Advantage of controlled warp beam solutions

— Use of larger or more warp beams

— Relief of the supplying plant in the knitting machine

— Each warp beam is individually controlled

— Perfect amount of yarn with the necessary tension

— Quality and performance improvement

Holistic view for customized solutions

As an engineering company, we rely on the development of innovative systems. Only a holistic view of textile technology, mechanics, electronics / electrical engineering, control technology makes it possible to optimally design systems. Our direct cooperation with customers and machine manufacturers as well as international research partners guarantees a regular transfer of know-how.