Introducing: remote maintenance of our new BLDC control for narrow and wide weaving.

The green solution

We use the TeamViewer platform for secure remote access to our BLDC control system to ensure environmentally friendly and resource-saving support.

It is no longer just computers that can be networked and operated remotely. The Internet of Things stands – far beyond the computer – for the networking of devices and machines.

We use this technology for commissioning, optimization or support in case of technical problems.

CORONA-Virus

Travel restrictions, such as those currently caused by the corona virus, as well as a fast connection to technical equipment, will in the future increase the sensitivity towards the many advantages of remote connectivity.

Modern information technologies, such as video conferencing, which is also possible with the TeamViewer platform, will also contribute to this.

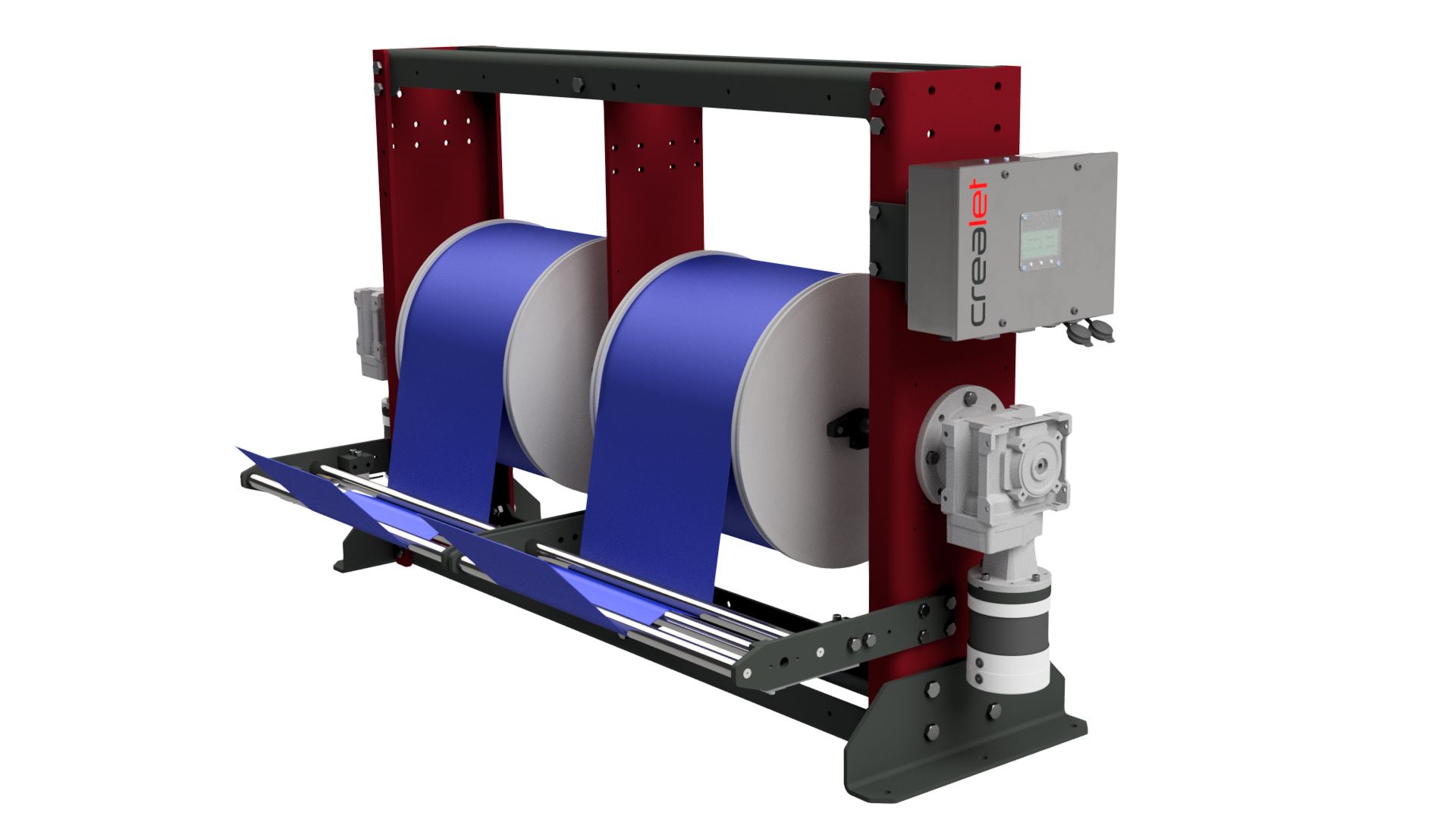

BLDC warp Let-Off

We solve your warp tension problems in narrow weaving with our new BLDC controls.

Every customer has very specific requirements. In order to be able to meet them, we carry out a thorough problem analysis. Then we work out proposals for the mechanics as well as for the necessary drive components.

The advantages of our solutions are:

- Reproducibility of production data

- Traceability of production and process data

- Fabric data storage

- Simple handling

- Network suitable

With our BLDC control system, narrow weaving mills take a big step towards digital transformation and set a decisive milestone for future success.