Innovations and new ideas at ITMA 2019

It’s time again: The international textile machinery exhibition ITMA will open its doors in Barcelona from 20 to 26 June 2019. We are looking forward to welcoming you at our stand A110 in Hall 4 and informing you about our innovative technologies for electronic warp feed for ribbon and wide looms.

Corporate Identity

CREALET AG is pleased to present its new company logo at ITMA 2019. The new appearance symbolizes values, quality and innovation using a simpler logo. The new, more up-to-date and contemporary font modernizes the image. The new logo is in line with the development of the company, with new products and services under the leadership of the next generation.

Innovation Priorities

Solutions for ribbon weaving

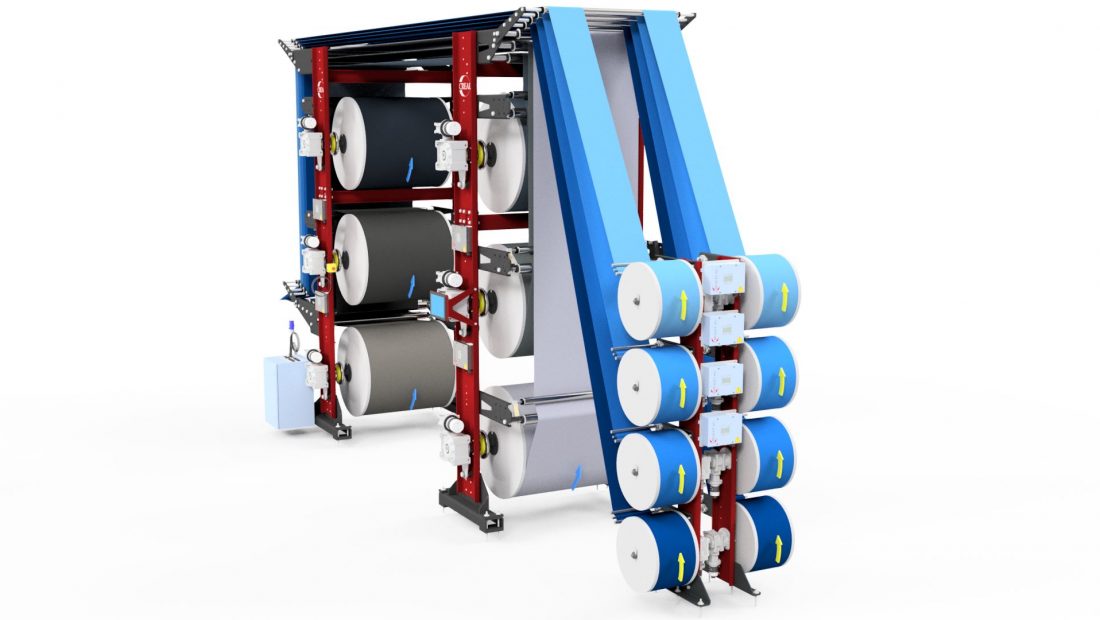

Warp feed system with “Linked Motion Control”

Discover the various innovations in our newly designed warp feed system with “Linked Motion Control” for controlling several warp beams behind the ribbon loom. Let our experts introduce and explain this new concept to you. With our new innovations, we support ribbon weavers in making warp feed more reliable, simpler and more efficient.

Industry 4.0 and the Internet of Things (IoT)

In the future, customers will demand even greater flexibility, taking their individual needs into account. Therefore, the production of the future must be able to react quickly to changing market requirements. Industry 4.0 is the answer to this challenge. Let us inform you about the future industry 4.0, applications in the field of warp feed.

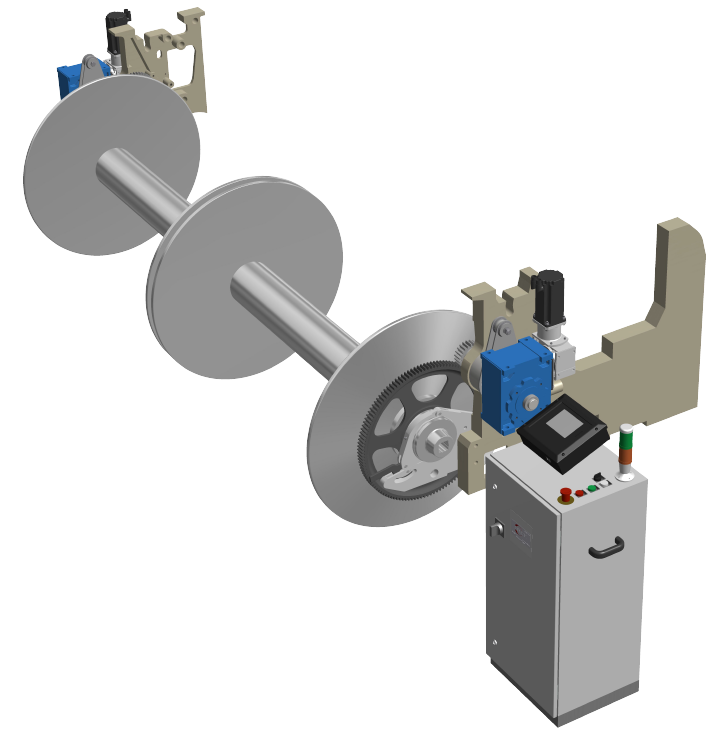

LT Let-Off Control

The new LT let-off control is designed for smaller warp beams, such as those found in narrow weaving or selvedge bobbins on wide looms. The warp tension is measured directly by a load cell. The SET and ACTUAL thread tension is indicated on the control unit display. The LT let-off control is exceptionally compact and equipped with many features about which we would like to inform you personally.

Solutions for wide weaving

Innovation with sustainability – a new life for your machines

It makes no sense to work with let-off devices that do not meet your requirements. Instead, discuss with us your wishes and requirements for upgrading your weaving machine in terms of warp feed.

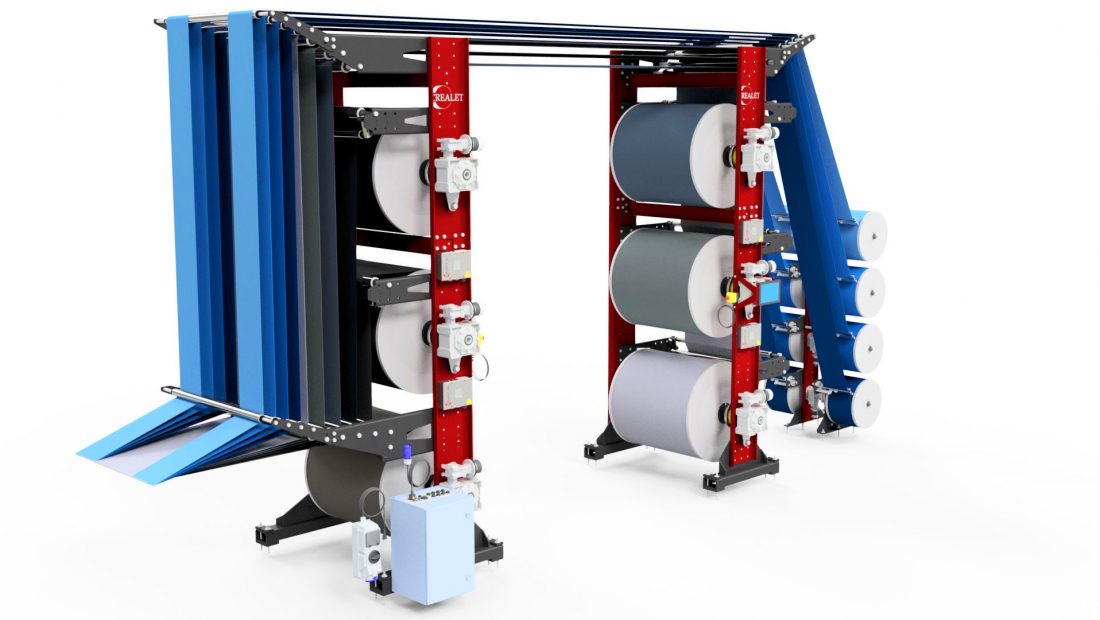

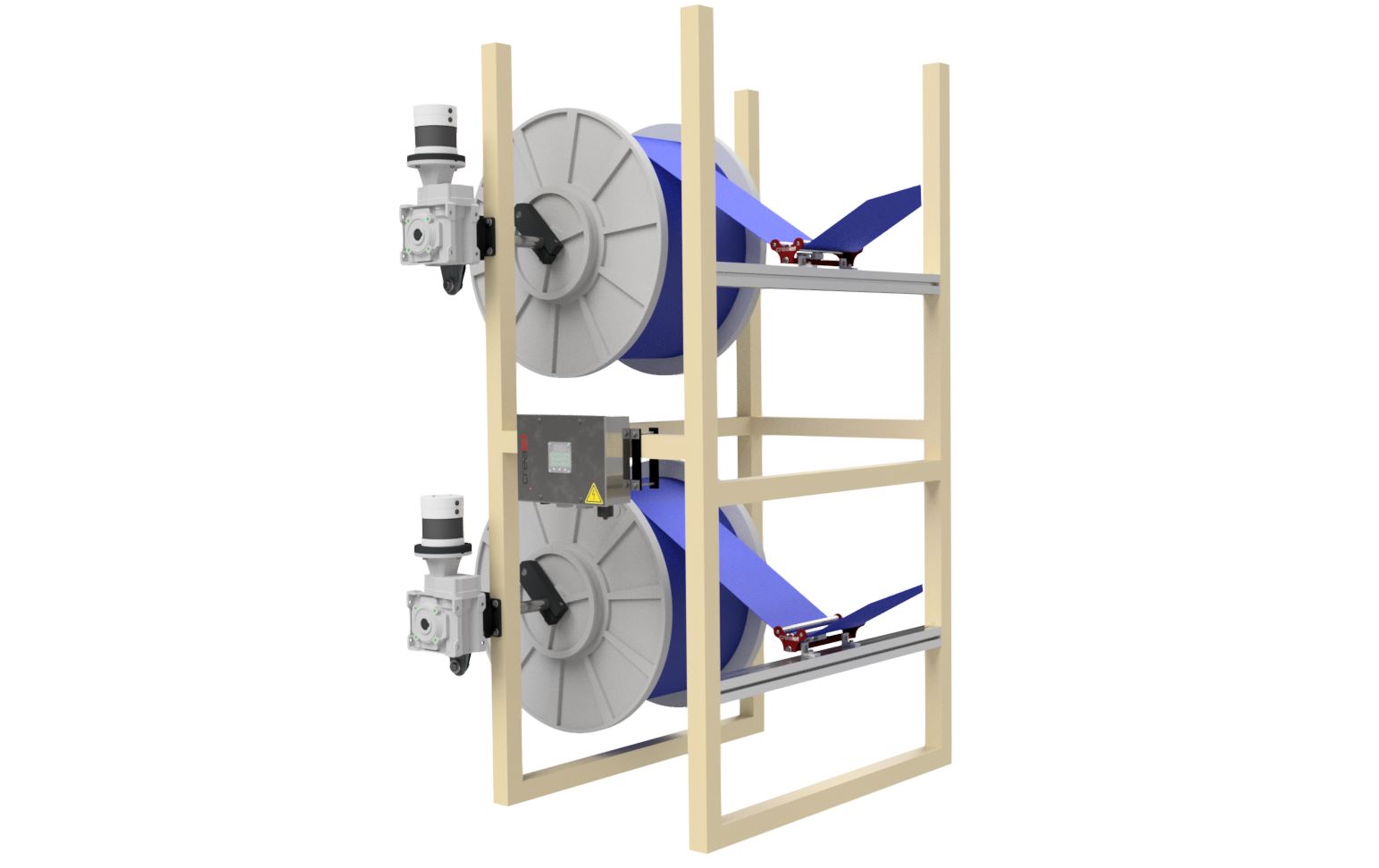

Textile Machines from COMSAT

We represent the company Construcciones Mataró Servicios y Asistencia Tecnica, known as COMSAT, in Germany and Switzerland. COMSAT is a leading manufacturer of direct and sectional warpers with the associated creels, thread tensioner for warp preparation in weaving, as well as winders for selvedge- and ribbon bobbins. In addition, ascending batch winders and fabric inspection machines with the necessary peripheral equipment are offered.

We are looking forward to presenting our latest innovations at ITMA 2019. Convince yourself of the innovations and advantages at our stand A110 in hall 4.