Warp tension control and warp feed systems

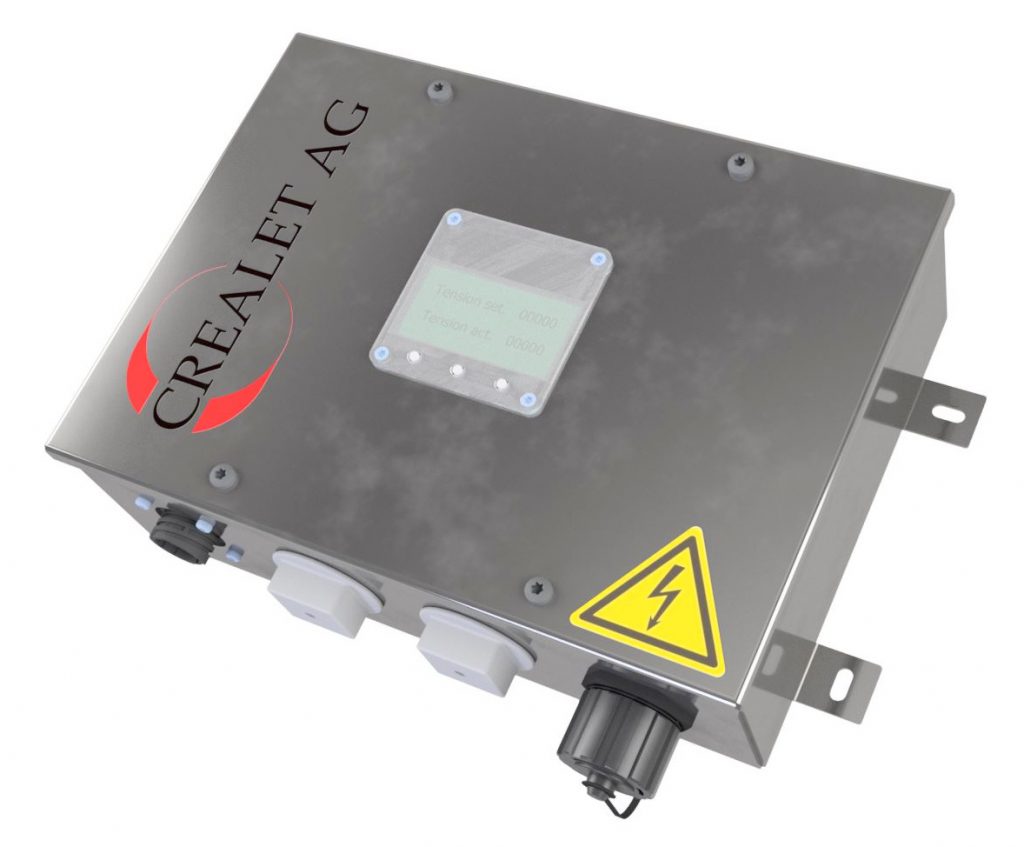

CREALET offers a comprehensive spectrum of products and professional service in the field of warp tension control and warp feeding systems to customers worldwide. The tailor-made control systems are all designed in-house.

By providing dedicated support over the complete life cycle, we guarantee that our solutions provide maximum benefit to our customers. As an innovation and technology-oriented family business with more than 15 years of experience, we have been dedicating ourselves to the values and passion for customer satisfaction.

Warp tension control

The purpose of a warp let-off system is to keep the warp yarns under a defined tension during weaving. If an existing system does not meet this requirement, upgrading can be the solution. CREALET develops warp tension control that can be integrated into existing system.

The entire warp tension control is based on closed-loop tension regulation with load cells or a dancer system that provides a measurement of the actual tension, which is then compared to the set tension.

Load Cell

Warp feed systems

The Executives in textile industry are working tirelessly to keep the efficiency and quality high. A significant potential of rationalization in the weaving mill is the reduction of the number of daily warp changes. This can be achieved by longer warp lengths. In view of this fact, the warp beam diameter plays an important role. The larger the dimeter of the beams the longer the length of warp which can be wound onto it. Weaving from several warp beams or from beams with bigger flange diameter increases efficiency and improves fabric quality.

CREALET designs and manufactures tailored warp feed systems for simple and complex applications in the narrow and wide weaving as well as for warp-knitting industries. Years of experience and expertise in this area as well as the cooperation with innovative partners speak for us.

Dual Drive