Warp thread feeding systems for the Narrow Weaving Industry

For weaving from sectional warp beams or creels, we develop and manufacture warp feeding units for the Narrow Weaving Industry. We offer specially designed creels and sectional warp beam frames according to your needs and wishes.

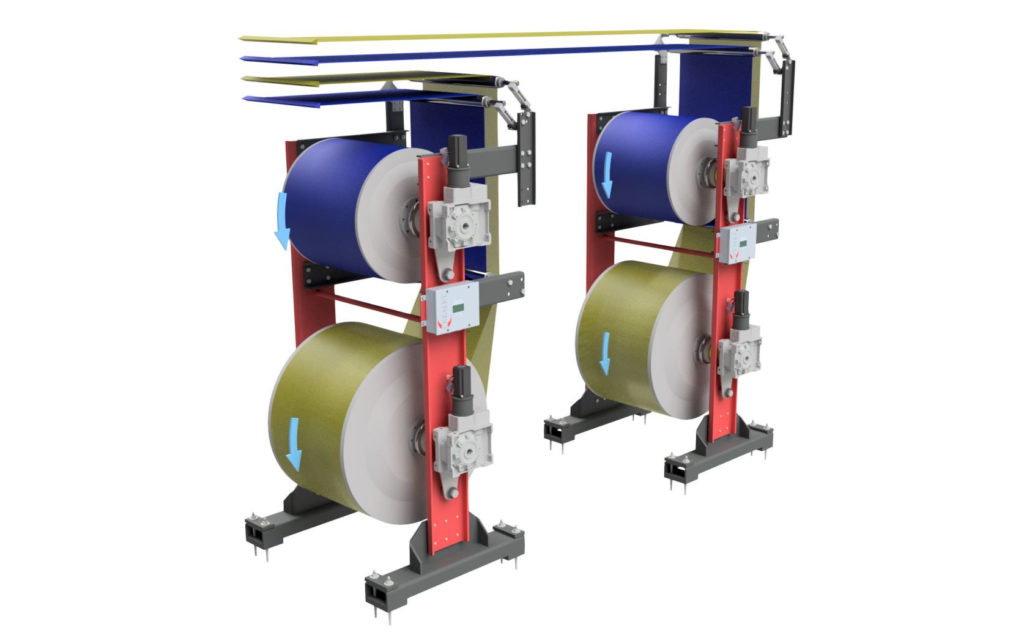

Warp beam frame with electronic warp let-off

Here is how it works

- The warp feed to the weaving machine takes place by means of an electronically controlled geared motor, controlled by our let-off control KAST.

- The thread tension is measured either via a spring-loaded sensing roller or a fixed measuring roller for the direct tension measurement of the warp threads.

- The drives are designed for the necessary weft densities and warp tensions.

- For a simple and safe change of the warp beam it is possible to use automatic safety chucks.

Improve fabric quality and machine efficiency

With our solutions you benefit from the following advantages:

- Optimized thread tension during the whole weaving process

- Higher quality assurance

- Reduced machine load

- Higher productivity

Conversion for existing warp beam frames

But we also have the opportunity and the experience of converting existing warp beams to electronic warp feed. This basically preserves the handling for the warp beam change.

If you would like more information about our products and services or if we can make you an offer, please contact us!

See also: Warp Thread Feed Systems for Narrow Weaving Machines