A guide to perfect tension control

This longer article takes a look on how to ensure the perfect tension during winding and unwinding operations. It is based on actual measuring data and shows you the challenge in controlling your web tension with a few illustration charts.

We always welcome your feedback.

Tension control plays an important role in different applications

During winding and unwinding operations, it is absolutely necessary that the web tension corresponds to the required processing operation. In the processing of textile fibers in weaving, knitting, braiding, filament winding and pultrusion processes, the tension control plays a decisive role in increasing the quality.

More and more attention is paid to tension control systems in order to achieve faster, automated and continuous processing. This is true not only in the textile industry but also in the production of composite material.

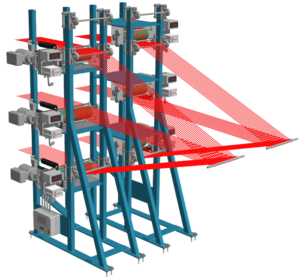

Unwinding station for warp knitting machines

Yarn feeding from creel

Web tension and tension control

The web tension is the load required during processing. Different web materials have different characteristics and thus have different tension requirements to ensure that they maintain their quality from start to finish.

Not enough or too much tension can cause a variety of problems and process errors. Defects such as stretching, folding, breaking, walking and more can exist when your web tension is not properly controlled.

The tension control is the process of maintaining a fixed tension of the web material between two points to maintain their desired characteristic and quality and to ensure that the material is processed in a defined way.

Tension control systems can most often be installed in existing processing systems – without the need to invest in new machines or in stand-alone units.

The difference between a manual and a closed control loop

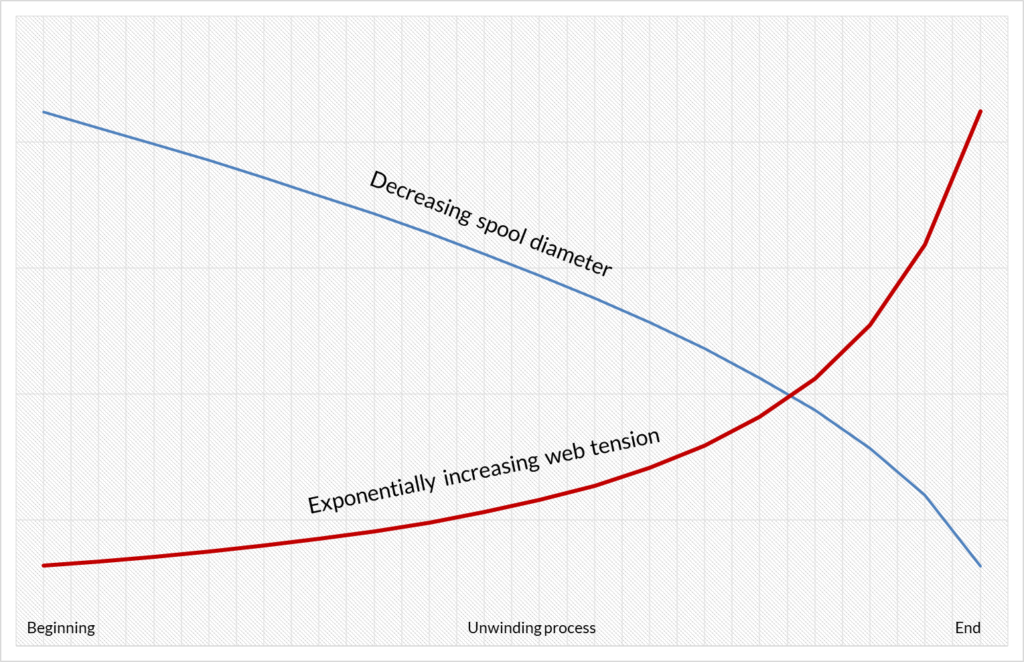

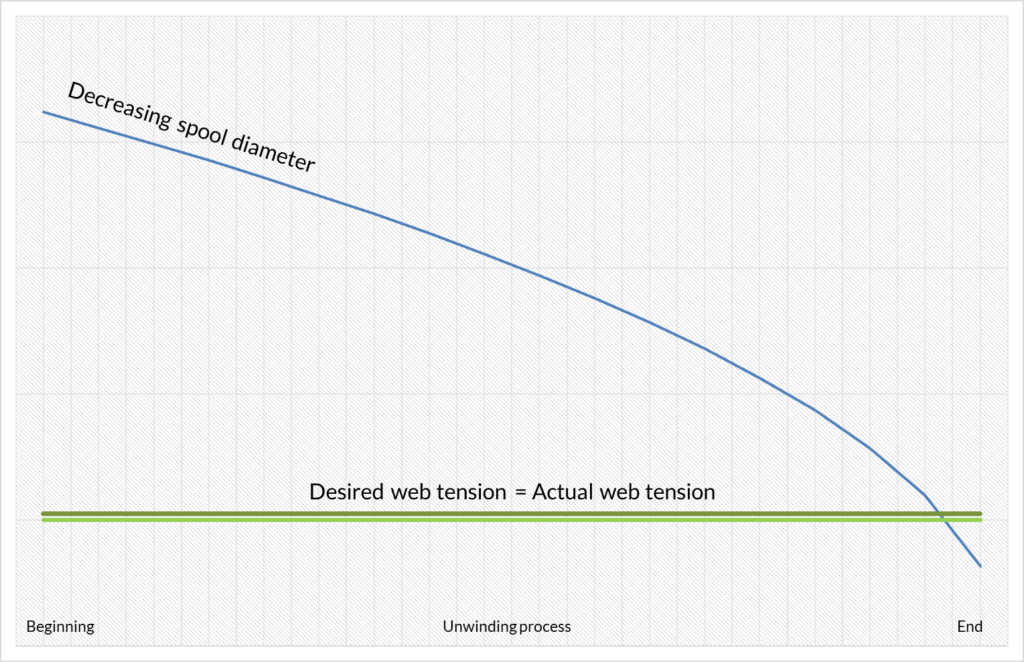

In the case of a constant braking effect on a flanged bobbin during an unwinding operation, the tension of the web material increases exponentially as a function of the diameter change. See what happens during the change of the spool diameter and the web tension during the unwinding process:

Web tension increase and spool diameter

Without a tension controller the web tension will increase or decrease as a function of the roller diameter. Deficiencies in the final product can be caused by web breaks due to excessive web tension or due to strength impairments caused by different web tensions within the web material.

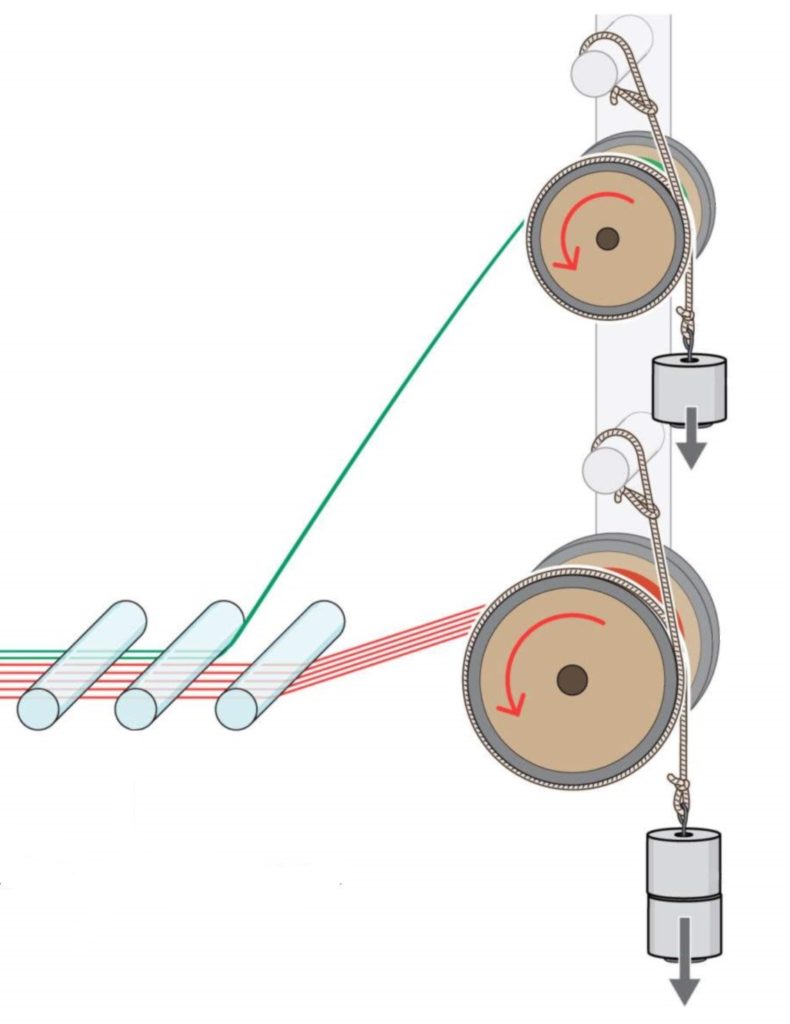

1) Working with a manual control loop

In the case of manual tension control, the web tension is subject to a “saw-tooth effect”, which is caused by the diameter reduction and the manual adjustments of the operator.

Maintaining the correct tension is becoming more and more difficult during the production process, since the web tension increases exponentially and the tension changes must be more frequently corrected.

This method is also exposed to the subjectivity of the various operators which typically results in uneven results.

Manual control with weights

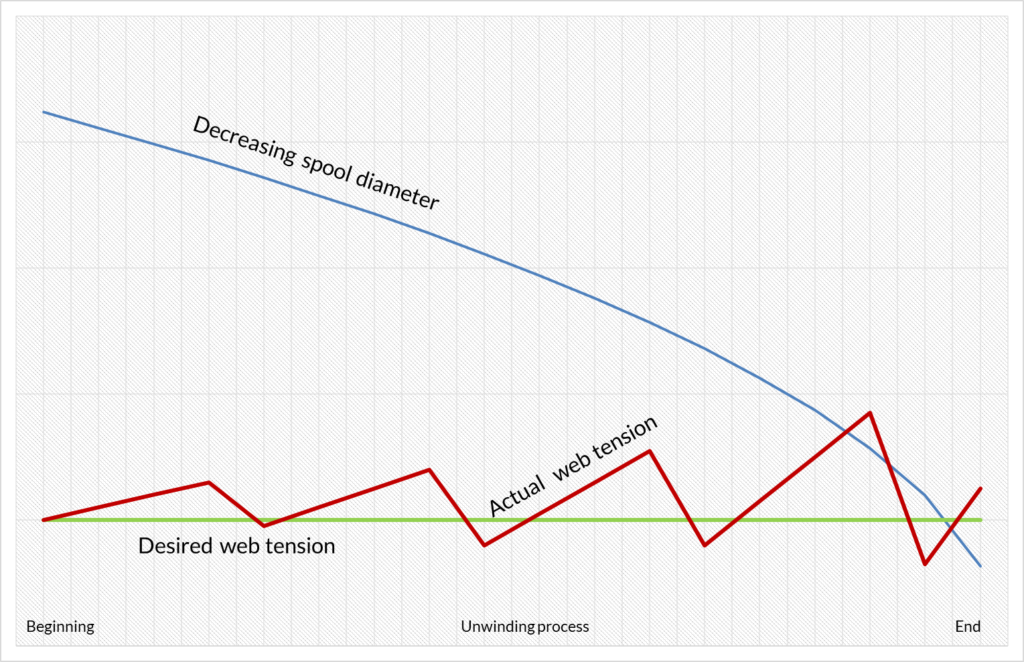

The saw-tooth effect

2) Working with a closed loop control

Measure: A closed loop control refers to a continuous flow of measured data from a web tension measurement device to a tension controller.

Transmit: The web tension can be measured by means of load cells or dancer position feedback sensors. The data of the continuous web tension measurement on the web material is directly transmitted to the tension regulator.

Compensate: The deviations to the desired tension are immediately compensated. This ensures a constant, uniform and precise web tension during the entire process.

Web tension with closed loop control

What CREALET can do for you

Crealet develops and manufactures complete tension controlled processing systems for warp threads and textile fibers for weaving-, knitting-, braiding-, filament winding- and pultrusion machines. Furthermore Crealet is specialized in incorporating the tension control technology into existing machines and devices.

We realize your ideas and support you from developing a new and efficient production process to commissioning. We will also be at your disposal during the entire life cycle of the machine with our competent service.

Solex 297

DIGIKAST

UKAST

Together with our customers we have implemented numerous special machines. Partnership and mutual trust are essential in the realization of new products and process innovations. Your competitive advantage and the secrecy of your specific knowledge is self-evident to us. For this reason we cannot show you any pictures of confidential projects which we have realized.

Please contact us if you have special requirements! Together we develop the optimal special machines for your requirements and production conditions.