The Challenge: Enormous warp yarn consumption

Due to coarse warp yarns and fabrics with low weft-density construction as well as high production of the weaving machines the consumption of warp material is enormous. For this reason the conventional way of weaving from standard warp beam is not economical.

The warp beam capacity can be reduced to a range of 1000 – 3000m by coarse warp yarn and flange diameter. This means in a very short time the warp beam is woven off and a new warp beam has to be brought to the machine. However, large fabric lengths are advantageous for further processing and longer warps lengths fulfil these conditions.

The following two methods are available for this purpose:

Weaving from sectional beams

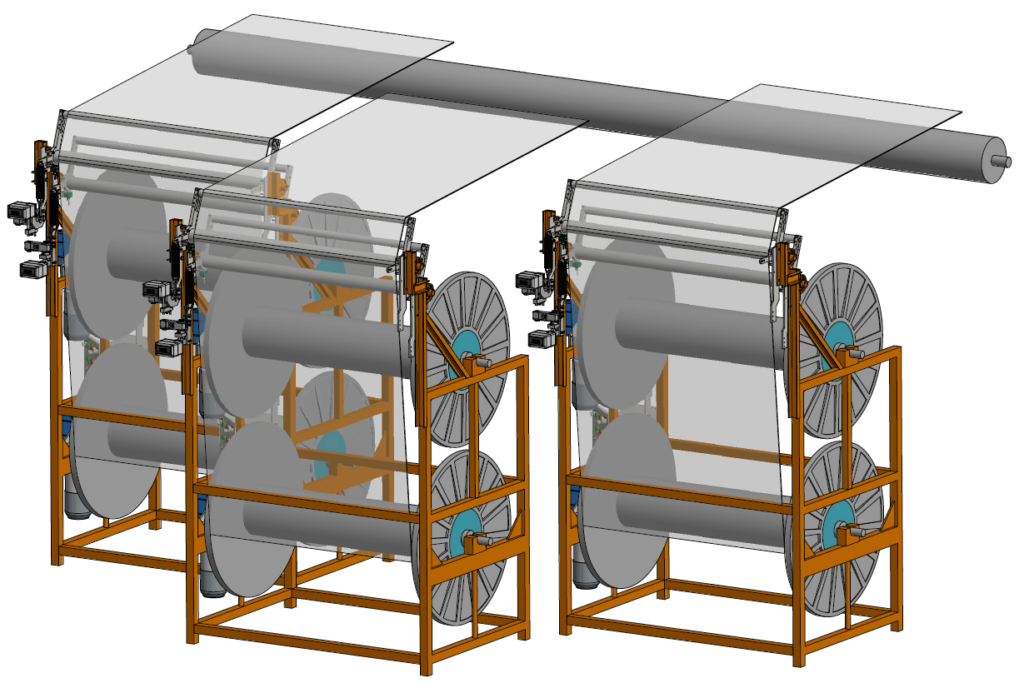

Weaving from several sectional warp beams can be done successfully with CREALET’s equipments. Depending on the required total number of warp ends 4 – 6 sectional beams, each warped with 400 to 600 ends, are directly placed behind the loom.

Weaving from creel

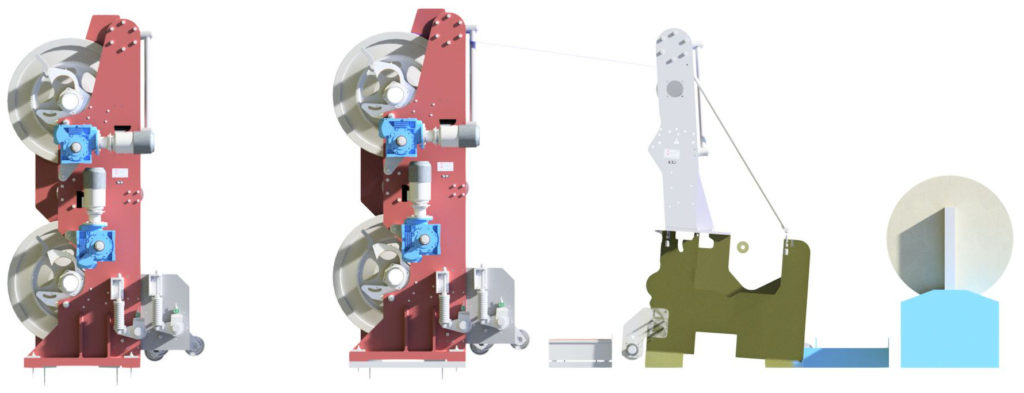

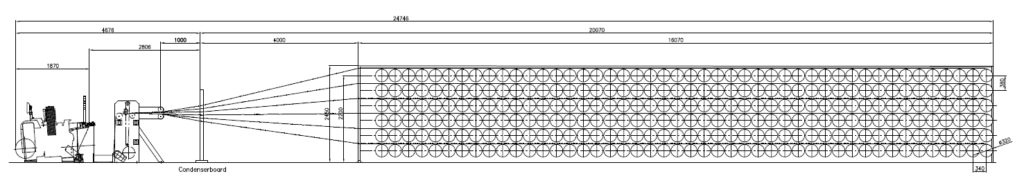

The other possibility is to feed the warp ends from the creel to the weaving machine. Often the warp yarn is drawn off tangentially from flanged bobbins or cross-wound bobbins through small comber boards with ceramic eyelet’s at the end of the creel. Thereafter they pass through a leasing reed and then are presented to the weaving machine by CREALET’s feeding device.

Should you have any further questions, please do not hesitate to contact us at any time.