Web tension control

Tension fluctuations can be the nightmare of any quality manager.

Once they occur, the risk is significantly higher to produce defective goods. Additional costs are incurred by delivering goods of poor quality or precious time is lost to solve the problem or missed delivery dates pose other, uncomfortable risks.

A precise tension control is important with every winding application where high quality is indispensable to produce the best product.

Mechanical feed systems where the spools are controlled by ropes and weights require an operator to continuously reduce the weight of the ever-decreasing roll. Today’s tension control frees this person from these manual tension corrections, as the constant web tension is guaranteed by the web tension control.

For this reason dancers and load cells – or a combination of both – are typically used on winding and unwinding devices. When used correctly, these systems are very accurate and provide a high degree of control.

Dancer control by CREALET

Principle of operation

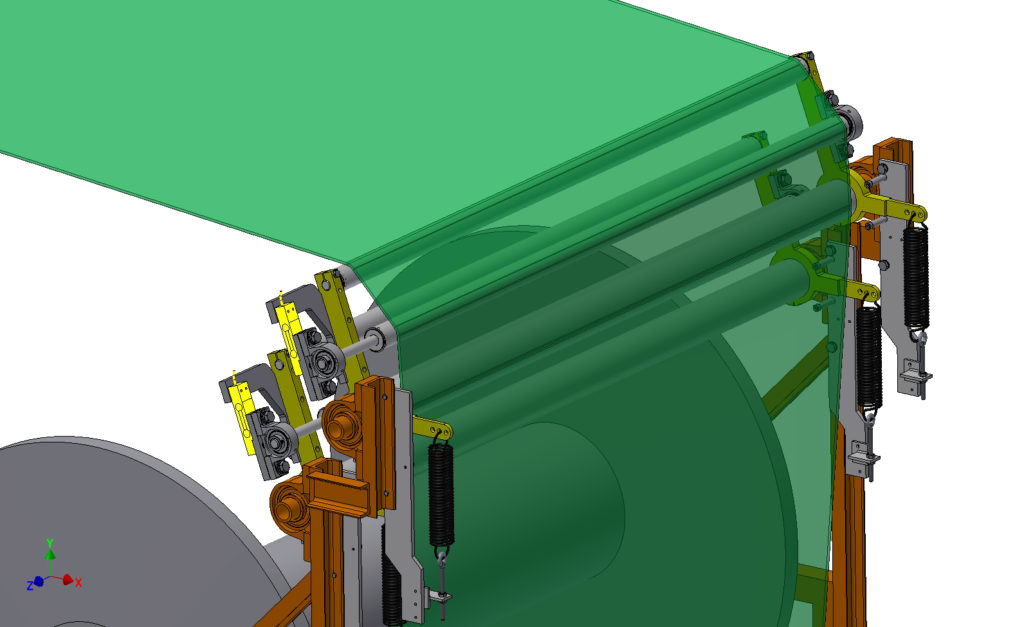

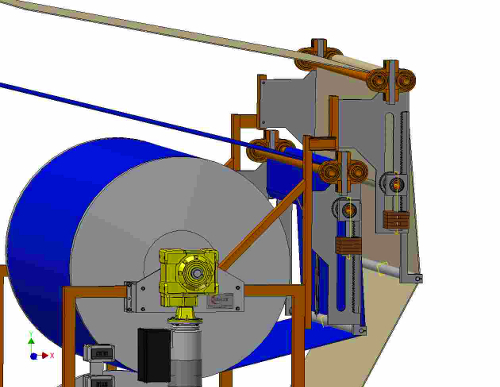

Weight loaded dancer by CREALET

The way in which the web tension is best regulated depends on the winding material to be processed, the process speed, web tension and the diameter range of the spools.

The tensile force exerted by an external force on the winding material is controlled with a dancer roller control. The roller is controlled with a drive motor for the general transport of the winding material, for example in the form of a spool drive instead of a braking system.

The unwinder has to follow the rewinder so that a desired tensile stress is established. This is achieved by the winding material experiencing a force, which corresponds to the required tensile stress, via a dancer roller.

A change in the dancer position in the positive or negative direction is fed to the speed controller of the drive motor and a speed correction leads to a direct correction of the dancer into its set point position.

CREALET – a strong, reliable partner for winding processes

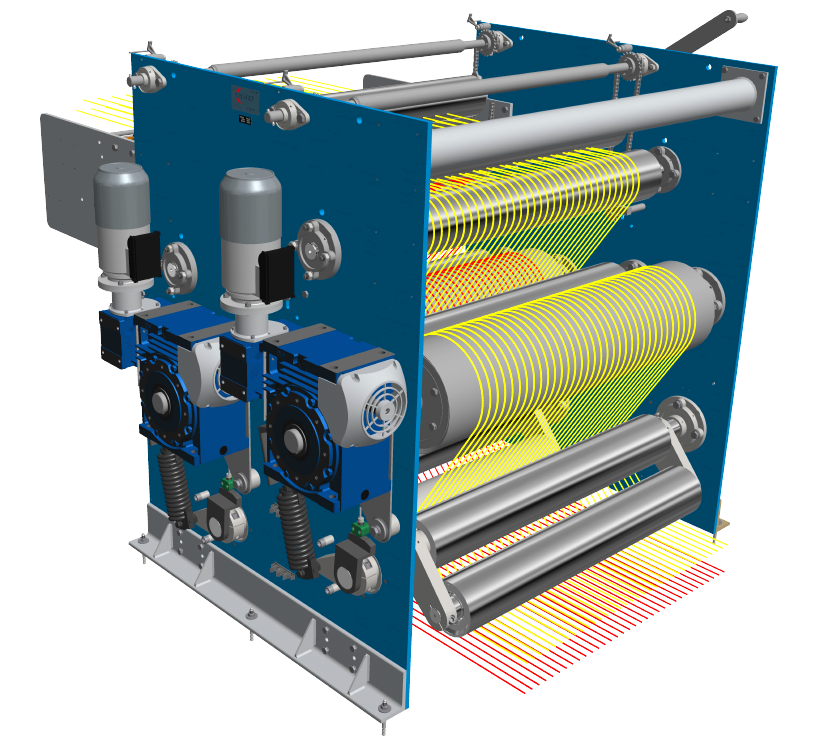

We are known as a supplier of innovative, customer-specific warp yarn feeders for narrow and wide weaving machines as well as warp knitting machines. We not only offer electronic controls, but also take responsibility for the design, manufacture and assembly of complete winding and unwinding systems.

Similar winding technologies which we use in the textile industry can also be used in many other production areas in which winding products such as cords, threads, fibers, ropes, wires, tapes, etc., can be produced or processed.

If you need support for your winding process, we would be glad to provide you appropriate solutions based on our many years of experience in the textile industry.

Double delivery unit by CREALET