Highly sophisticated bionics

75 years ago the story of hook & loop tapes started. The Swiss engineer Georges de Mestral noticed after a hunting trip with his dog the good clinging properties of the prickly heads of the burdock fruits on his clothes and on his dog’s fur. An example of bionics.

Fascinated by this phenomenon he carefully studied this fruit and discovered hundreds of tiny hooks at the end of the burr. This tiny hooks can easily catch loops. Following this model, he developed together with a textile enthusiast two cotton tapes that worked.

Unfortunately, the cotton worn out very quickly. Based on this experience he experimented with synthetic fibers. Through trial and error, he eventually discovered that nylon forms – nearly indestructible – were perfect for the hook side of the fastener when treated under infrared light.

In all, it took ten years to create a mechanized manufacturing process for hook and loop tapes that worked. He submitted his idea for patent in Switzerland in 1951 and the patent was granted in 1955. De Mestral named his new product “Velcro”, a combination of the French words velour and crochet.

Hook-and-loop fastening systems are a great development and are everywhere nowadays and nobody could imagine to be without them now.

The inventiveness of nature is as ingenious as it is versatile. Based on this knowledge the interdisciplinary field of bionics came about. Hook and loop tapes are widely known as an example of bionics. Bionics is the science that studies nature’s best ideas and then imitates these designs and processes to create more efficient, elegant, and sustainable products.

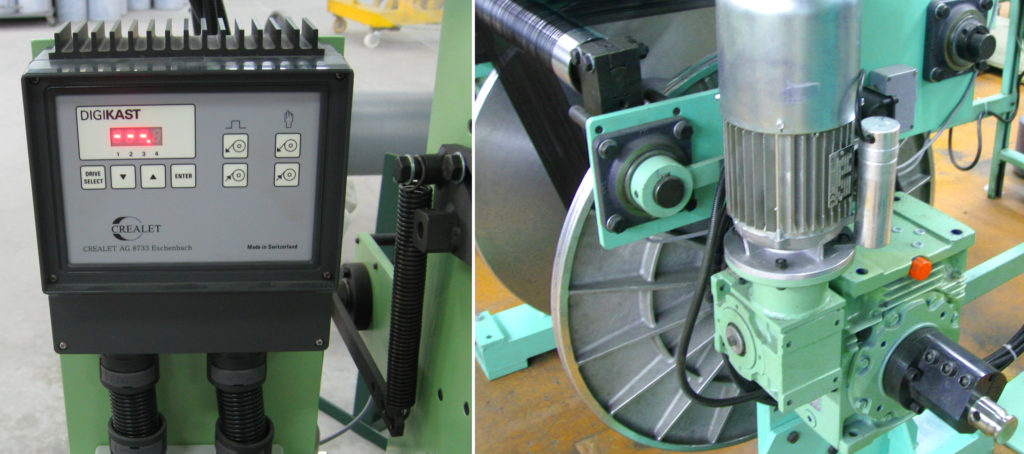

Electronic tension controls by CREALET for hook & loop tapes production.

CREALET supports its customers in optimizing the weaving process for hook and loop tapes with electronic warp let-off motion.

Existing mechanical let-offs can cause a high degree of irregularities in density, particularly with high speed weaving machines. Not only existing systems can be modified for better quality and efficiency but also custom made warp beam frames can be a big success.

For more specific information please contact us.